Professional Stainless Steel Wire Mesh Manufacturer and Stockist from China.

Feel free to call or email our senior sales.

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

Pure Titanium Wire Mesh

Material: Ta1 wires and Ta2 wires.

Type: Industrial Exotic Wire Mesh

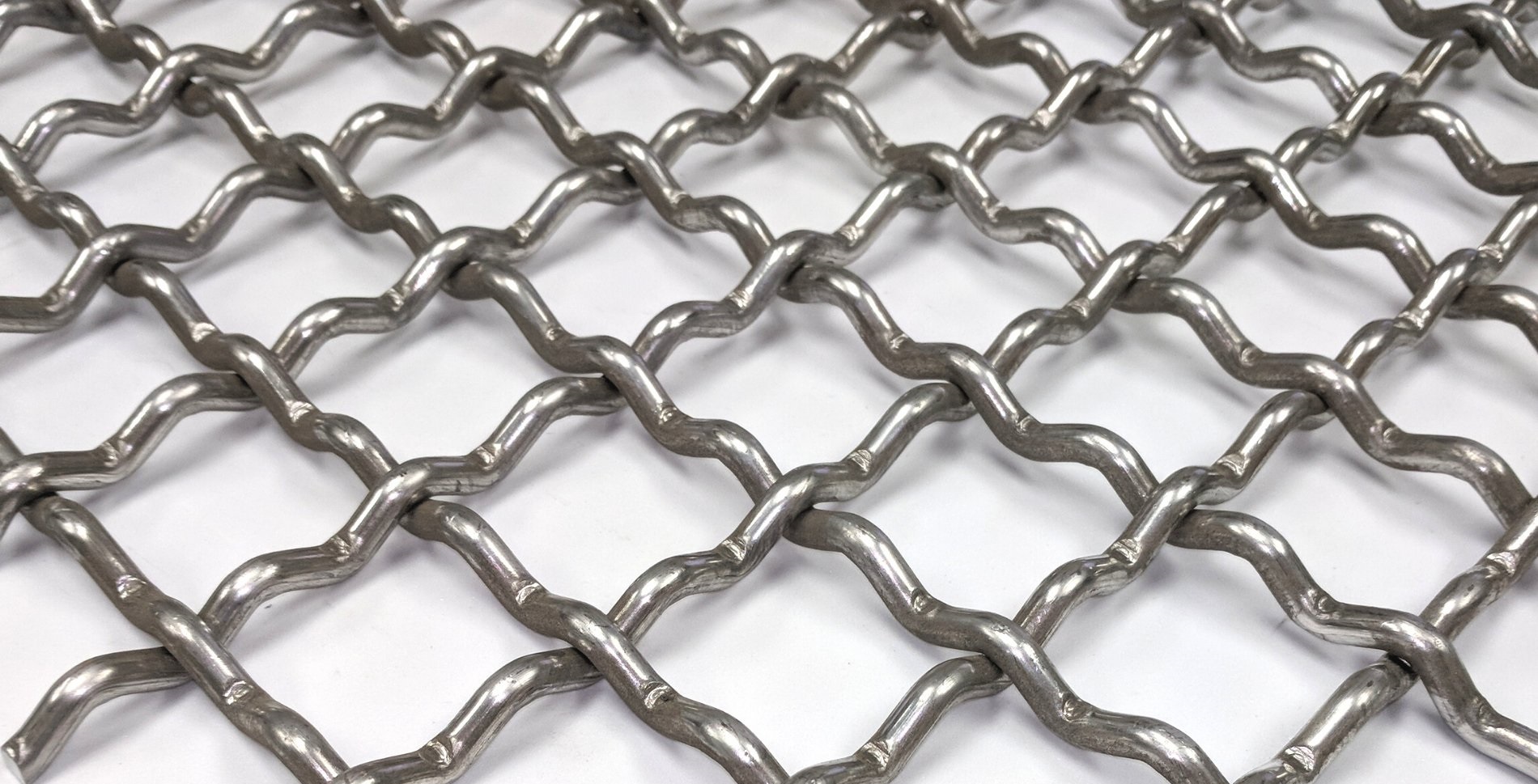

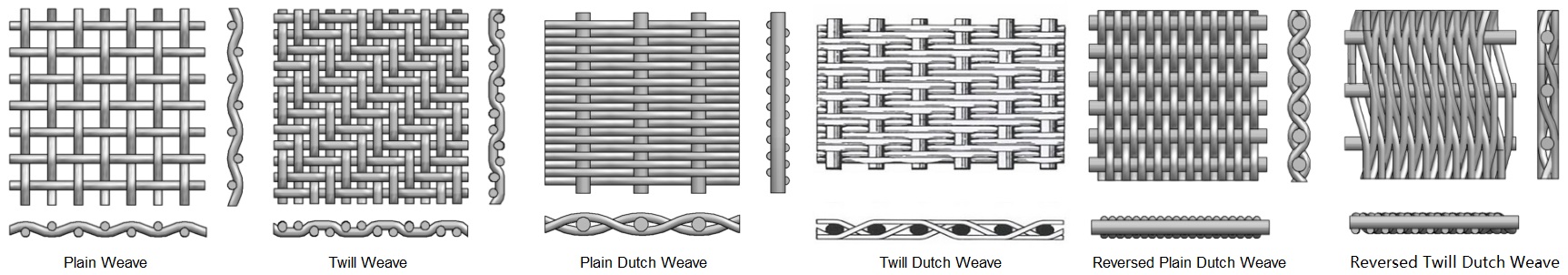

Patterns of Weave: Plain and Twill Weave, Dutch Weave and Crimped Weaving.

Mesh Count: Customized

Wire Dia.: Customized.

Roll Width: Customized size.

Roll Length: Standard 30 meters roll and other customized size.

Titanium wire mesh is produced from quality titanium wires that are recognized for their high strength, lightweight, and corrosion resistance, making it a popular material in a wide range of sectors.

Titanium wire mesh is produced from quality titanium wires that are recognized for their high strength, lightweight, and corrosion resistance, making it a popular material in a wide range of sectors.

Commercially Pure (CP) Titanium alloy wire mesh contains greater than 99 percent titanium. A protective oxide layer is usually present on titanium wire mesh to prevent electrolytic interactions with other metals. Using titanium wire mesh baskets can increase the efficiency of the anodizing process for aluminum components.

Bright Titanium wire mesh (white Titanium wire mesh) is distinguished from Black Titanium wire mesh by its visual appearance. Both are composed of pure titanium wires. White Titanium mesh contains no imperfections on its surface, making it ideal for anodizing studies, catalyst carrier supports, pure chemical liquid filtration, and the filtration of other uncontaminated solutions. However, the surface of the black titanium mesh comprises a coating of graphite emulsion that is suitable for seawater desalination and chemical filtering. The coating on the surface can inhibit corrosion and extend durability.

There are two grades of titanium wire mesh that are routinely utilized.

TA1 wire mesh, UNS R50250 wire mesh, and W.Nr. 3.7025 wire mesh are alternate names for CP Titanium Grade 1 wire mesh.

Grade 1 titanium has the highest ductility and corrosion resistance of all titanium grades. It possesses superior cold-forming qualities, welding properties, and impact resistance. Titanium wire mesh of grade 1 is frequently employed in the architectural, medical, maritime, and chemical processing industries.

|

EQUIVALENT STANDARDS OF TITANIUM WOVEN WIRE MESH |

|||

|

INDUSTEEL TRADEMARKS |

UNS |

EURONORMS EN |

SUS |

|

TA1 WIRE MESH |

UNS R50250 WIRE MESH |

3.7025 WIRE MESH |

… |

|

TA2 WIRE MESH |

UNS R50400 WIRE MESH |

3.7035 WIRE MESH |

… |

Chemical Composition of CP TA1 and TA2 wire mesh

|

Grade |

Fe % |

C % |

N % |

H % |

O % |

Ti |

|

TA1 Mesh |

0.2 Max |

0.08 Max |

0.03 Max |

0.015 Max |

0.18 Max |

Balance |

|

TA2 Mesh |

0.3 Max |

0.1 Max |

0.03 Max |

0.015 Max |

0.25 Max |

Balance |

Physical Properties of TA1 Titanium wire mesh

|

Property of TA1 Alloy Wire & Mesh |

|

|

Density |

4.51g/cm3 / 0.163lb/in³ |

|

Melting Range |

Max 1670 °C / Max 3040 °F |

|

Liquidus |

1670 °C / 3040 °F |

|

Thermal Conductivity (annealed) |

16 W/m-K / 111 BTU-in/hr-ft²-°F |

|

Specific Heat Capacity |

0.52 J/g-°C / 0.124 BTU/lb-°F |

|

Electrical Resistivity |

4.5e-005 ohm-cm / 4.5e-005 ohm-cm |

|

Hardness, Brinell (anneal) |

120 / 120 |

|

Hardness, Knoop (estimated data according to Brinell) |

132 / 132 |

|

Hardness, Rockwell B |

70 / 70 |

|

Hardness, Vickers (estimated data according to Brinell) |

122 / 122 |

|

Max Tensile Strength |

240 MPa / 34800 psi |

|

Tensile Strength, Yield |

170-310 MPa / 24700-45000 psi |

|

Elongation at Rupture |

24% / 24% |

|

Reduction of Area |

35% / 35% |

|

Modulus of Elasticity (In tension) |

105 GPa / 15200 ksi |

|

Compressive Modulus |

110 GPa / 16000 ksi |

Physical Properties of TA2 Titanium wire and mesh

|

Property of TA2 Alloy Wire & Mesh |

|

|

Density |

4.51g/cm3 / 0.163lb/in³ |

|

Melting Range |

Max 1665 °C / Max 3030 °F |

|

Liquidus |

1665 °C / 3030 °F |

|

Thermal Conductivity (annealed) |

16.4 W/m / 114 BTU-in/hr-ft²-°F |

|

Specific Heat Capacity |

0.523 J/g-°C / 0.125 BTU/lb-°F |

|

Electrical Resistivity |

5.2e-005 ohm-cm / 5.2e-005 ohm-cm |

|

Hardness, Knoop |

170 / 170 |

|

Hardness, Rockwell B |

80 / 80 |

|

Hardness, Vickers |

145 / 145 |

|

Max Tensile Strength |

344 MPa / 49900 psi |

|

Tensile Strength, Yield |

275-410 MPa / 39900-59500 psi |

|

Elongation at Rupture |

20% / 20% |

|

Reduction of Area |

35% / 35% |

|

Modulus of Elasticity (In tension) |

105 GPa / 15200 ksi |

|

Compressive Modulus |

110 GPa / 16000 ksi |

Regular Specification Table of plain weave and twill weave pure Titanium alloy mesh.

|

Mesh Count Mesh/Inch |

Wire Diameter |

Aperture |

Open Area % |

Weight (LB) /100 Square Foot |

||

|

Inch |

MM |

Inch |

MM |

|||

|

1 × 1 |

.080 |

2.03 |

.920 |

23.37 |

84.6 |

41.1 |

|

2 × 2 |

.063 |

1.60 |

.437 |

11.10 |

76.4 |

51.2 |

|

3 × 3 |

.054 |

1.37 |

.279 |

7.09 |

70.1 |

56.7 |

|

4 × 4 |

.063 |

1.60 |

.187 |

4.75 |

56.0 |

104.8 |

|

4 × 4 |

.047 |

1.19 |

.203 |

5.16 |

65.9 |

57.6 |

|

5 × 5 |

.041 |

1.04 |

.159 |

4.04 |

63.2 |

54.9 |

|

6 × 6 |

.035 |

.89 |

.132 |

3.35 |

62.7 |

48.1 |

|

8 × 8 |

.028 |

.71 |

.097 |

2.46 |

60.2 |

41.1 |

|

10 × 10 |

.025 |

.64 |

.075 |

1.91 |

56.3 |

41.2 |

|

10 × 10 |

.020 |

.51 |

.080 |

2.03 |

64.0 |

26.1 |

|

12 × 12 |

.023 |

.584 |

.060 |

1.52 |

51.8 |

42.2 |

|

12 × 12 |

.020 |

.508 |

.063 |

1.60 |

57.2 |

31.6 |

|

14 × 14 |

.023 |

.584 |

.048 |

1.22 |

45.2 |

49.8 |

|

14 × 14 |

.020 |

.508 |

.051 |

1.30 |

51.0 |

37.2 |

|

16 × 16 |

.018 |

.457 |

.0445 |

1.13 |

50.7 |

34.5 |

|

18 × 18 |

.017 |

.432 |

.0386 |

.98 |

48.3 |

34.8 |

|

20 × 20 |

.020 |

.508 |

.0300 |

.76 |

36.0 |

55.2 |

|

20 × 20 |

.016 |

.406 |

.0340 |

.86 |

46.2 |

34.4 |

|

24 × 24 |

.014 |

.356 |

.0277 |

.70 |

44.2 |

31.8 |

|

30 × 30 |

.013 |

.330 |

.0203 |

.52 |

37.1 |

34.8 |

|

30 × 30 |

.012 |

.305 |

.0213 |

.54 |

40.8 |

29.4 |

|

30 × 30 |

.009 |

.229 |

.0243 |

.62 |

53.1 |

16.1 |

|

35 × 35 |

.011 |

.279 |

.0176 |

.45 |

37.9 |

29.0 |

|

40 × 40 |

.010 |

.254 |

.0150 |

.38 |

36.0 |

27.6 |

|

50 × 50 |

.009 |

.229 |

.0110 |

.28 |

30.3 |

28.4 |

|

50 × 50 |

.008 |

.203 |

.0120 |

.31 |

36.0 |

22.1 |

|

60 × 60 |

.0075 |

.191 |

.0092 |

.23 |

30.5 |

23.7 |

|

60 × 60 |

.007 |

.178 |

.0097 |

.25 |

33.9 |

20.4 |

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY