Professional Stainless Steel Wire Mesh Manufacturer and Stockist from China.

Feel free to call or email our senior sales.

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

Inconel Wire Mesh and Inconel Wire Cloth

Material: Inconel 600 wires, Inconel 601wires, Inconel 625 wires

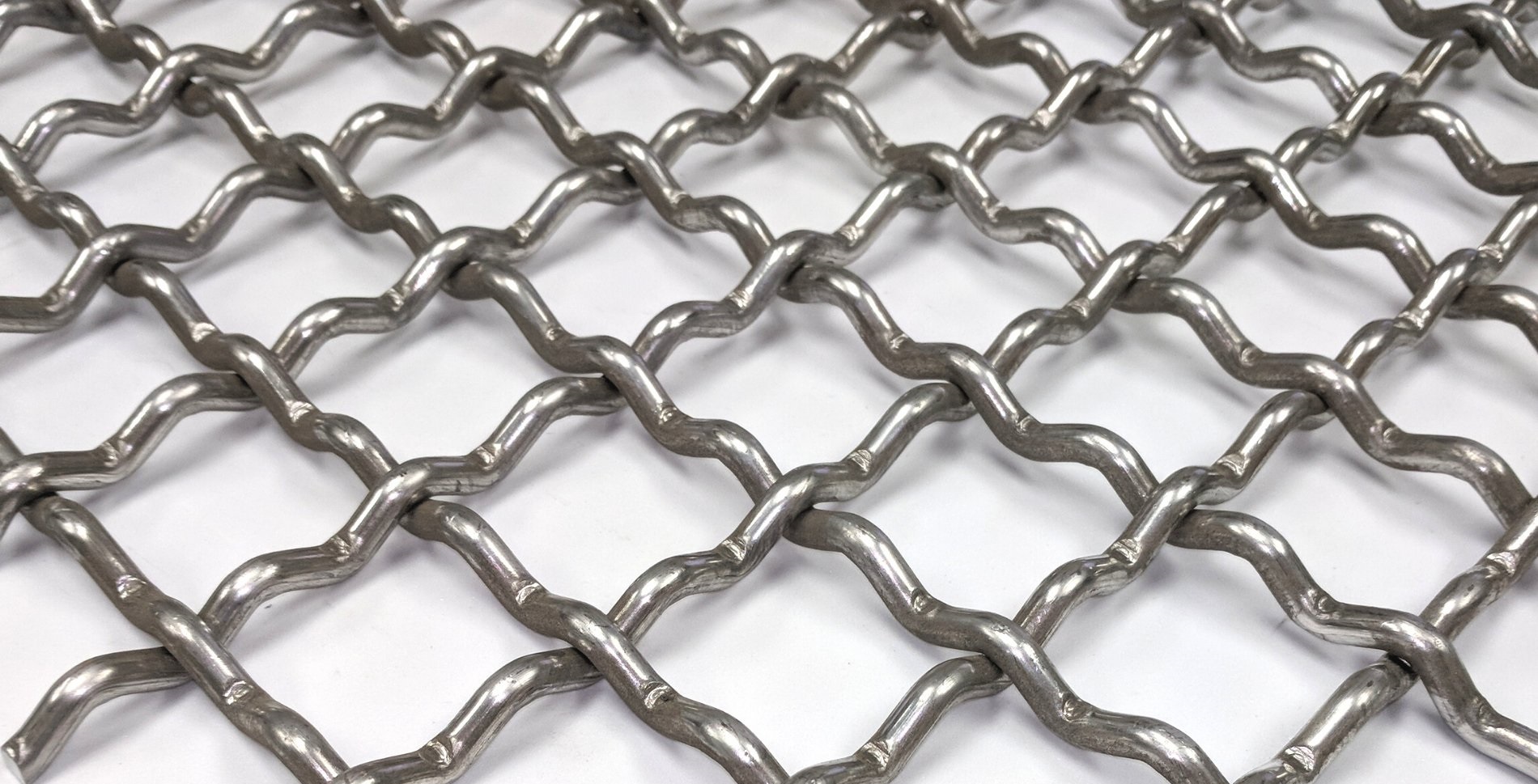

Type: Industrial Woven Wires

Type of Weave: Plain and Twill Weave, Plain and Dutch Weave, Crimped Weave, etc.

Mesh Count: Customized

Wire Diameter: Customized

Roll Width: Customized

Roll Length: 30 meter and other customized length.

.jpg) METART Inconel wire mesh and wire cloth include mainly three different types, Inconel 600 wire mesh, Inconel 601 wire mesh, and Inconel 625 wire mesh. The wire mesh can be produced by either welding or weaving. Woven Inconel wire mesh is our specialty whereas we can also produce Inconel welded wire mesh in standard rolls or flad sheets based on customers' requirements. For other Inconel wire mesh grades, please inquire about one of our sales representatives for availability.

METART Inconel wire mesh and wire cloth include mainly three different types, Inconel 600 wire mesh, Inconel 601 wire mesh, and Inconel 625 wire mesh. The wire mesh can be produced by either welding or weaving. Woven Inconel wire mesh is our specialty whereas we can also produce Inconel welded wire mesh in standard rolls or flad sheets based on customers' requirements. For other Inconel wire mesh grades, please inquire about one of our sales representatives for availability.

#1, Inconel 600 Wire Mesh and Wire Cloth.

Alloy 600 wire mesh is well known by its brand name Inconel® 600 wire mesh which is basically a super alloy that is mainly consisted of nickel and chromium elements and famous for its superior oxidation resistance properties under higher temperatures.

Inconel 600 woven wire is a very versatile wire mesh that can be applied in many areas from cryogenics to applications that present elevated temperatures up to 2000°F (1093°C).

With high nickel content combined with its chromium content, alloy 600 wire cloth provides users with a lot of benefits including high oxidation resistance at high temperatures, excellent corrosion resistance to both organic and inorganic compounds, and good resistance to chloride-ion stress corrosion crackings.

Inconel 600 wire cloth performs very well in most alkaline solutions and sulfur compounds. Due to its versatility, alloy 600 woven wire fabric becomes the standard engineering material for those applications that need resistance to corrosion and heat, a lot of different critical industries have to use Inconel 600 wire mesh and 600 wire cloth in their production process

|

EQUIVALENT STANDARDS of ALLOY 600 WIRE MESH |

||||

|

ALLOY 600 |

UNS |

ASTM |

EURONORMS EN |

SUS |

|

Inconel 600 Wire Mesh |

N06600 Wire Mesh |

N06600 Wire Mesh |

EN 2.4816 Wire Mesh |

|

Chemical Composition of Nickel Alloy 600 wire mesh.

|

C % |

Mn % |

S % |

Si % |

Ni % |

Cr % |

Fe % |

|

0.10Max |

1.0 Max |

0.015 Max |

0.50 Max |

72.0 Min |

14.0-17.0 |

6.0-10.0 |

Physical Properties of Inconel 600 wire mesh.

|

Physical Property |

°F |

British Units |

°C |

Metric Units |

|

Density |

Room Temperature |

0.304 lb./cubic in. |

Room Temperature |

8.43g/cubic cm |

|

Electrical Resistivity |

70 |

40.6 microohm-in. |

21 |

1.03 microohm-m |

|

200 |

40.9 |

93 |

1.04 |

|

|

400 |

41.5 |

204 |

1.05 |

|

|

600 |

42.2 |

316 |

1.07 |

|

|

800 |

43 |

427 |

1.09 |

|

|

Mean Coefficient of Thermal Expansion |

70-200 |

7.4 microinches/in.-°F |

21-93 |

13.3 x 10(-6)m/m·K |

|

70-400 |

7.7 |

21-204 |

13.9 |

|

|

70-600 |

7.9 |

21-316 |

14.2 |

|

|

70-800 |

8.1 |

21-427 |

14.6 |

|

|

Thermal Conductivity |

70 |

103 Btn-in./ft².-hr.-°F |

21 |

14.8 W/m·K |

|

200 |

109 |

93 |

15.7 |

|

|

400 |

121 |

204 |

17.4 |

|

|

600 |

133 |

316 |

19.2 |

|

|

800 |

145 |

427 |

20.9 |

|

|

Modulus of Elasticity |

Room Temperature |

30.0 x 10(6) psi |

Room Temperature |

207 GPa |

#2, Inconel 601 Wire Mesh and Wire Cloth.

Inconel 601 is the brand name of nickel alloy 601. METART Inconel 601 wire mesh is also referred to as UNS N06601 wire mesh and 2.4851 wire mesh.

Alloy 601wire mesh is also produced by quality nickel-chromium alloy wires. This alloy has an extra addition of aluminum element which offers high mechanical properties even in extremely hot environments.

This nickel alloy mesh stands out due to its resistance to high-temperature oxidation, remaining highly resistant to oxidation through 2200° F (1093°C).

Inconel 601 alloy develops a tightly adherent oxide scale that resists spalling even under conditions of severe thermal cycling.

The wire mesh made of this 601 alloy has good high-temperature strength and retains its ductility after long service exposure. Meantime the wire mesh has a very high mechanical strength and good resistance to aqueous corrosion. Alloy 601 is easy to machine, weld, and form. All of these properties make 601 alloy wire mesh material of broad utility in industries and areas including catalyst supports, chemical processing, heat processing, exhaust systems, nuclear exchanger, pollution control, aerospace units, etc.

However, Inconel 601 mesh and filter screens are not recommended for applications in strongly reducing, sulfur-bearing environments.

Theoretically, the material of alloys 600 and 601 costs about the same. But alloy 600 material is more widely used and there are more materials circulating on the market which makes the alloy 600 mesh products less expensive. Generally, if the alloy 600 material can meet your requirement, please consider it first.

But sometimes, we may also have some alloy 601 wire mesh in stock, that would make the price competitive, please inquire with our sales team about the availability.

|

EQUIVALENT STANDARDS of ALLOY 601 WIRE MESH |

||||

|

ALLOY 601 |

UNS |

ASTM |

EURONORMS EN |

SUS |

|

Inconel 601 Wire Mesh |

N06601 Wire Mesh |

N06601 Wire Mesh |

EN 2.4851 Wire Mesh |

… |

Chemical Composition of Nickel Alloy 601 Wire Cloth

|

C % |

Mn % |

S % |

Si % |

AL % |

Ni % |

Cr % |

Fe % |

|

0.10Max |

1.5 Max |

0.015 Max |

0.50 Max |

1.0-1.7 |

58.0-63.0 |

21-25 |

~16 |

Physical Properties of Inconel 601 Wire Screens.

|

Physical Property |

Metric Units |

|

Density |

8,110 kg/m³ at 20°C |

|

Melting Point |

1360-1411°C |

|

Electrical Resistivity |

1190 micro-ohm . m @ 20°C |

|

Specific Heat |

448 J/kg . °C @ 20°C |

|

Mean Coefficient of Expansion |

13.8 x 10-6 / °C @ 20°C |

|

Thermal Conductivity |

11.2 W / m . °C @ 20°C |

|

Curie Temperature |

-320°C |

|

Tension |

207 GPa @ 20°C |

|

Torsion |

81.2 GPa @ 20°C |

|

Poisson’s Ratio |

0.272 @ 20°C |

#3, Inconel 625 Wire Cloth

Inconel 625 wire cloth is the brand name of Nickel Alloy 625 wire cloth which is also widely known by its UNS name N06625 mesh or W.Nr. 2.4856 wire cloth. Similar to 600 and 601 alloy wire screens, the 625 alloy wire screen is a nickel-chromium alloy with an addition of around 8 percent of molybdenum for outstanding resistance to reduction and other forms of high-temperature corrosion, servicing temperatures ranging from cryogenic to 1800°F (982°C).

The high percentage of nickel content plays a very important role in corrosion resistance, even though Inconel 625 wire mesh contains a relatively lower percentage of nickel elements than Inconel 600 mesh, both of them are very good corrosion-resistant alloy mesh.

The Chromium content of alloy 625 wire mesh is higher than alloy 600 which is helpful to enhance the oxidation resistance to this alloy. Therefore, alloy 625 woven wire cloth or wire mesh has a better oxidation resistance property than alloy 600 wire mesh.

Inconel 625 alloy has more than 8% molybdenum, which makes Inconel 625 wire mesh have a certain resistance to reduction which is not available in Alloy 600 and 601.

Based on the above-mentioned parameters, alloy 625 woven wire products has better comprehensive corrosion resistance than alloy 600 and 601 mesh.

Similar to the molybdenum element, the extra additions of niobium and tantalum also enhance the mechanical properties of Inconel 625 wire mesh products. Alloy 625 is strictly controlled by the content of impurities, including phosphorus and manganese. The large content of phosphorus may lead to the precipitation of harmful phases, thereby affecting the properties of the alloy.

And the alloy would reduce the creep performance at high temperatures if there is too much manganese content.

Therefore, wire mesh and filter products made of Inconel 625 wires always have a higher purity than Inconel 600 and 601. Meantime it would also perform a bit better than those wire mesh products made of 600 and 601 alloy wires.

|

EQUIVALENT STANDARDS of ALLOY 625 WIRE MESH |

||||

|

ALLOY 625 |

UNS |

ASTM |

EURONORMS EN |

JIS |

|

Inconel 625 Wire Mesh |

N06625 Wire Mesh |

N06625 Wire Mesh |

EN 2.4856 Wire Mesh |

NCF 625 Wire Mesh |

Chemical Composition of Nickel Alloy 625 Wire Cloth

|

Ni % |

Cr % |

Fe % |

Mo % |

Nb % |

Co % |

Mn % |

Al % |

Ti % |

Si % |

C % |

S % |

P % |

|

58.0 Max |

20.0-23.0 |

5 |

8.0-10.0 |

3.15-4.15 |

1.0 Max |

0.50 Max |

0.4 Max |

0.4 Max |

0.50 Max |

0.10 Min |

0.015 Max |

0.015 Max |

Physical Properties of Inconel 625 Wire Cloth

|

Physical Properties of Alloy 625 Wire Mesh |

|

|

Density |

8.4 g/cm3 |

|

Melting Point |

2460 °F (1350°C) |

|

Tensile Strength |

930MPA Psi-135,000 , |

|

Yield Strength (0.2%Offset) |

Psi-75,000, MPa-517 |

|

Elongation Rate |

42.5% |

Regular Specification Table

|

Mesh / Inch |

Wire Diameter |

Aperture Size |

Open Rate % |

||

|

Inch |

MM |

Inch |

MM |

||

|

1 × 1 |

.080 |

2.03 |

.920 |

23.37 |

84.6 |

|

2 × 2 |

.063 |

1.60 |

.437 |

11.10 |

76.4 |

|

3 × 3 |

.054 |

1.37 |

.279 |

7.09 |

70.1 |

|

4 × 4 |

.063 |

1.60 |

.187 |

4.75 |

56.0 |

|

4 × 4 |

.047 |

1.19 |

.203 |

5.16 |

65.9 |

|

5 × 5 |

.041 |

1.04 |

.159 |

4.04 |

63.2 |

|

6 × 6 |

.035 |

.89 |

.132 |

3.35 |

62.7 |

|

8 × 8 |

.028 |

.71 |

.097 |

2.46 |

60.2 |

|

10 × 10 |

.025 |

.64 |

.075 |

1.91 |

56.3 |

|

10 × 10 |

.020 |

.51 |

.080 |

2.03 |

64.0 |

|

12 × 12 |

.023 |

.584 |

.060 |

1.52 |

51.8 |

|

12 × 12 |

.020 |

.508 |

.063 |

1.60 |

57.2 |

|

14 × 14 |

.023 |

.584 |

.048 |

1.22 |

45.2 |

|

14 × 14 |

.020 |

.508 |

.051 |

1.30 |

51.0 |

|

16 × 16 |

.018 |

.457 |

.0445 |

1.13 |

50.7 |

|

18 × 18 |

.017 |

.432 |

.0386 |

.98 |

48.3 |

|

20 × 20 |

.020 |

.508 |

.0300 |

.76 |

36.0 |

|

20 × 20 |

.016 |

.406 |

.0340 |

.86 |

46.2 |

|

24 × 24 |

.014 |

.356 |

.0277 |

.70 |

44.2 |

|

30 × 30 |

.013 |

.330 |

.0203 |

.52 |

37.1 |

|

30 × 30 |

.012 |

.305 |

.0213 |

.54 |

40.8 |

|

30 × 30 |

.009 |

.229 |

.0243 |

.62 |

53.1 |

|

35 × 35 |

.011 |

.279 |

.0176 |

.45 |

37.9 |

|

40 × 40 |

.010 |

.254 |

.0150 |

.38 |

36.0 |

|

50 × 50 |

.009 |

.229 |

.0110 |

.28 |

30.3 |

|

50 × 50 |

.008 |

.203 |

.0120 |

.31 |

36.0 |

|

60 × 60 |

.0075 |

.191 |

.0092 |

.23 |

30.5 |

|

60 × 60 |

.007 |

.178 |

.0097 |

.25 |

33.9 |

|

70 × 70 |

.0065 |

.165 |

.0078 |

.20 |

29.8 |

|

80 × 80 |

.0065 |

.165 |

.0060 |

.15 |

23.0 |

|

80 × 80 |

.0055 |

.140 |

.0070 |

.18 |

31.4 |

|

80 × 80 |

.0047 |

.119 |

.0078 |

.198 |

39 |

|

90 × 90 |

.005 |

.127 |

.0061 |

.16 |

30.1 |

|

100 × 100 |

.0045 |

.114 |

.0055 |

.14 |

30.3 |

|

100 × 100 |

.004 |

.102 |

.0060 |

.15 |

36.0 |

|

100 × 100 |

.0035 |

.089 |

.0065 |

.17 |

42.3 |

|

110 × 110 |

.0040 |

.1016 |

.0051 |

.1295 |

30.7 |

|

120 × 120 |

.0037 |

.0940 |

.0064 |

.1168 |

30.7 |

|

150 × 150 |

.0026 |

.0660 |

.0041 |

.1041 |

37.4 |

|

160 × 160 |

.0025 |

.0635 |

.0038 |

.0965 |

36.4 |

|

180 × 180 |

.0023 |

.0584 |

.0033 |

.0838 |

34.7 |

|

200 × 200 |

.0021 |

.0533 |

.0029 |

.0737 |

33.6 |

|

250 × 250 |

.0016 |

.0406 |

.0024 |

.0610 |

36.0 |

|

270 × 270 |

.0016 |

.0406 |

.0021 |

.0533 |

32.2 |

|

300 × 300 |

.0051 |

.0381 |

.0018 |

.0457 |

29.7 |

|

325 × 325 |

.0014 |

.0356 |

.0017 |

.0432 |

30.0 |

|

400 × 400 |

.0010 |

.0254 |

.0015 |

.370 |

36.0 |

-Nuclear reactor vessels and heat exchanger tubing

-Chemical processing industry.

-Heat-treating furnace components

-Electronic parts

-Aerospace parts.

-Parts of food processing equipment.

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY