Professional Stainless Steel Wire Mesh Manufacturer and Stockist from China.

Feel free to call or email our senior sales.

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

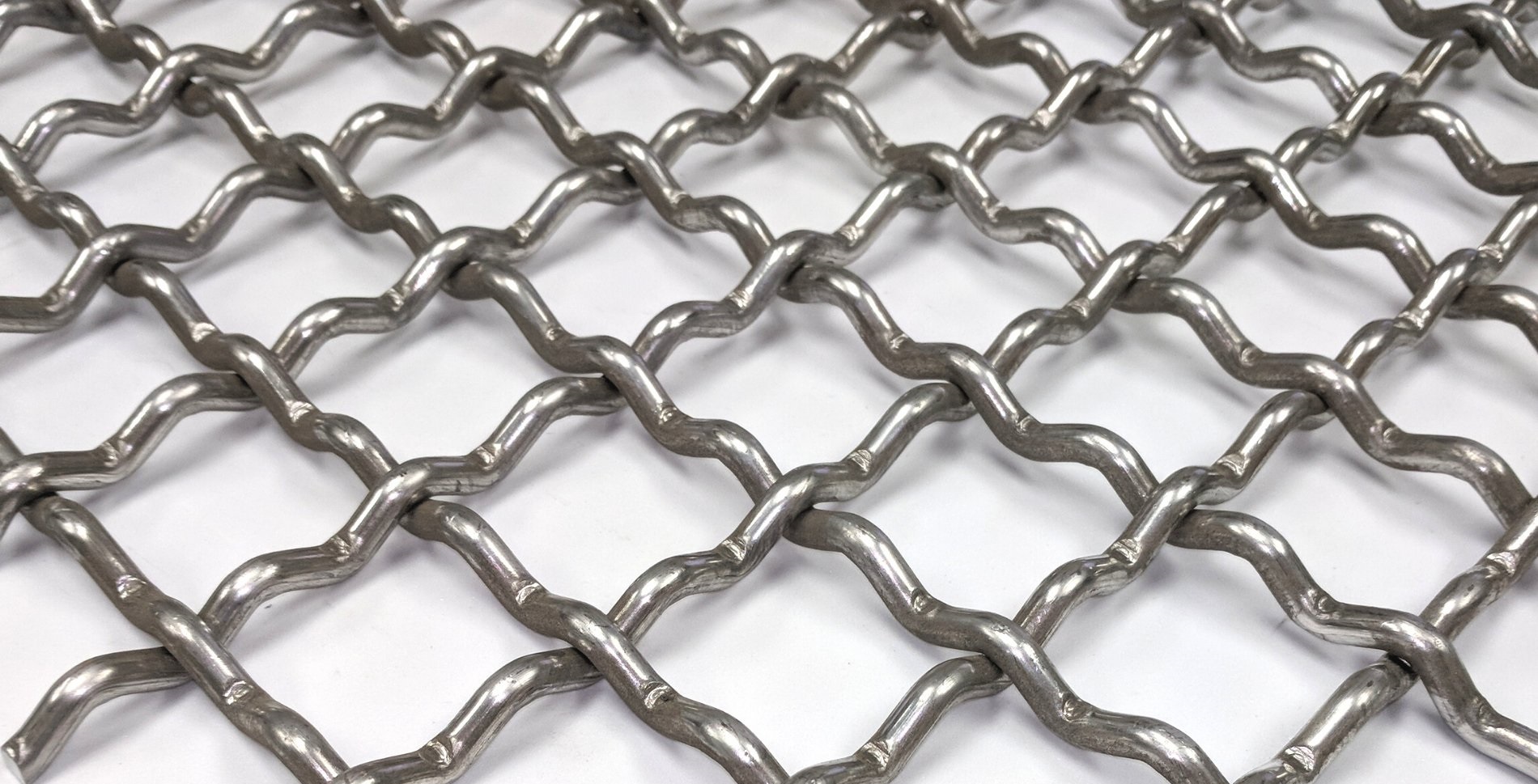

nichrome-wire-mesh

Material: Nichrome alloy wires.

Type: Industrial exotic alloy wires

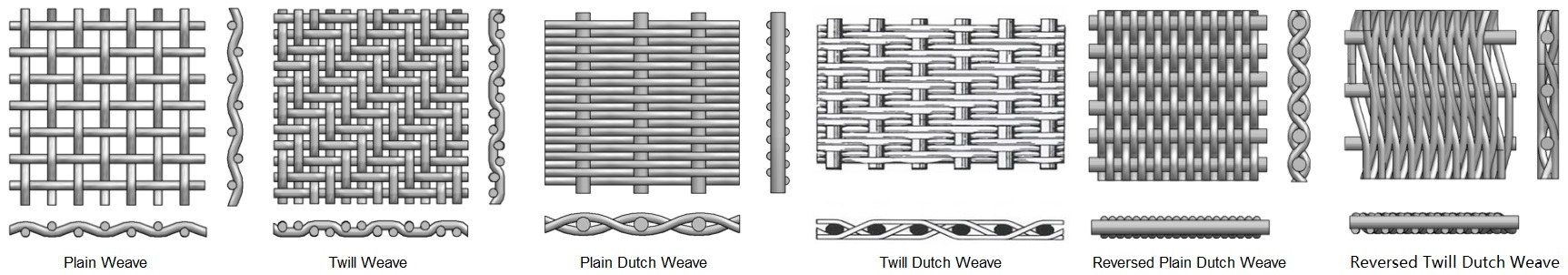

Pattern of Weave: Plain and twill weave, Dutch Weave, Crimped Weave Pattern.

Mesh Count: Customized.

Wire Diameter: Customized

Roll Width: Customized

Roll Length: 30 meters and other customized size

Nichrome wire mesh is also well known by the public other names such as Nickel-Chromium wire mesh, Chromium-Nickel wire mesh, and NiCr mesh for short. This alloy wire mesh belongs to a family of alloys of Nickel, Chromium, iron, and a few other elements.

It is documented that Nichrome alloy is the earliest air-stable resistance-heating alloy which was patented in 1906.

As a high nickel austenitic alloy, Nichrome wire mesh and screen products are typically used for this high resistance and a maximum working temperature of 1,250°C (2,280°F).

The basic material to fabricate the mesh is Nichrome wires which are often used as resistance wire, heating elements in appliances like toasters, electrical kettles, and space heaters, as well as in some dental restorations (fillings).

The most commonly used NiCr screen mesh is 8020 Nichrome wire mesh, which is also known as 80/20 NiCr Wire Mesh, and Cr20Ni80 wire mesh. It is produced with mainly around 80 percent of Nickel and 20 percent of Chromium. But, in order to meet different market requirements, there are quite a lot of different combinations of Nickel and Chromium elements for different applications.

METART is a manufacturer as well as a stockiest of special alloy wire mesh rolls, please contact our sales team to check the availability of nichrome wire cloth rolls or wire mesh sheets. Customized combinations are accepted even for small orders.

|

EQUIVALENT STANDARDS OF 8020 NICHROME WIRE MESH |

||||

|

INDUSTEEL TRADEMARKS |

UNS |

ASTM |

EURONORMS EN |

SUS |

|

N06003 WIRE MESH |

N06003 WIRE MESH |

EN 2.4869 WIRE MESH |

… |

|

Chemical Composition of Cr20Ni80 wire mesh

|

Ni % |

Cr % |

Al % |

Cu % |

Fe % |

Mn % |

S % |

P % |

Si % |

C % |

|

75.0 Min |

19.0- 21.0 |

0.3 Max |

0.5 Max |

1.0 Max |

1.0 Max |

0.015 Max |

0.02 Max |

0.5- 2.0 |

0.15 Max |

Physical Properties of different combinations of Nichrome wire mesh.

|

Physical Properties |

Cr20Ni80 |

Cr30Ni70 |

Cr15Ni60 |

Cr20Ni35 |

Cr20Ni30 |

|

Density(g/cm3) |

8.31 |

8.1 |

8.2 |

7.9 |

7.9 |

|

Melting point approx.( ºC) |

1400 |

1380 |

1390 |

1390 |

1390 |

|

Max. continuous service temp. of element(ºC) |

1200 |

1250 |

1150 |

1100 |

1100 |

|

Resistivity at 20ºC (μΩ·m) |

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

Thermal conductivity (KJ/m·h·ºC) |

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

Coefficient of lines expansion (α×10-6/ºC) |

18 |

17 |

17 |

19 |

19 |

|

Elongation at rupture(%) |

>20 |

>20 |

>20 |

>20 |

>20 |

|

Micrographic structure |

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

Magnetic properties |

Nonmagnetic |

Nonmagnetic |

Nonmagnetic |

Weak magnetic |

Weak magnetic |

Regular Specification Table of plain weave and twill weave NiCr alloy 80/20 filter mesh

|

/Inch |

Wire Diameter |

Aperture |

Open Area % |

Weight (LB) /100 Square Foot |

||

|

Inch |

MM |

Inch |

MM |

|||

|

1 × 1 |

.080 |

2.03 |

.920 |

23.37 |

84.6 |

41.1 |

|

2 × 2 |

.063 |

1.60 |

.437 |

11.10 |

76.4 |

51.2 |

|

3 × 3 |

.054 |

1.37 |

.279 |

7.09 |

70.1 |

56.7 |

|

4 × 4 |

.063 |

1.60 |

.187 |

4.75 |

56.0 |

104.8 |

|

4 × 4 |

.047 |

1.19 |

.203 |

5.16 |

65.9 |

57.6 |

|

5 × 5 |

.041 |

1.04 |

.159 |

4.04 |

63.2 |

54.9 |

|

6 × 6 |

.035 |

.89 |

.132 |

3.35 |

62.7 |

48.1 |

|

8 × 8 |

.028 |

.71 |

.097 |

2.46 |

60.2 |

41.1 |

|

10 × 10 |

.025 |

.64 |

.075 |

1.91 |

56.3 |

41.2 |

|

10 × 10 |

.020 |

.51 |

.080 |

2.03 |

64.0 |

26.1 |

|

12 × 12 |

.023 |

.584 |

.060 |

1.52 |

51.8 |

42.2 |

|

12 × 12 |

.020 |

.508 |

.063 |

1.60 |

57.2 |

31.6 |

|

14 × 14 |

.023 |

.584 |

.048 |

1.22 |

45.2 |

49.8 |

|

14 × 14 |

.020 |

.508 |

.051 |

1.30 |

51.0 |

37.2 |

|

16 × 16 |

.018 |

.457 |

.0445 |

1.13 |

50.7 |

34.5 |

|

18 × 18 |

.017 |

.432 |

.0386 |

.98 |

48.3 |

34.8 |

|

20 × 20 |

.020 |

.508 |

.0300 |

.76 |

36.0 |

55.2 |

|

20 × 20 |

.016 |

.406 |

.0340 |

.86 |

46.2 |

34.4 |

|

24 × 24 |

.014 |

.356 |

.0277 |

.70 |

44.2 |

31.8 |

|

30 × 30 |

.013 |

.330 |

.0203 |

.52 |

37.1 |

34.8 |

|

30 × 30 |

.012 |

.305 |

.0213 |

.54 |

40.8 |

29.4 |

|

30 × 30 |

.009 |

.229 |

.0243 |

.62 |

53.1 |

16.1 |

|

35 × 35 |

.011 |

.279 |

.0176 |

.45 |

37.9 |

29.0 |

|

40 × 40 |

.010 |

.254 |

.0150 |

.38 |

36.0 |

27.6 |

|

50 × 50 |

.009 |

.229 |

.0110 |

.28 |

30.3 |

28.4 |

|

50 × 50 |

.008 |

.203 |

.0120 |

.31 |

36.0 |

22.1 |

|

60 × 60 |

.0075 |

.191 |

.0092 |

.23 |

30.5 |

23.7 |

|

60 × 60 |

.007 |

.178 |

.0097 |

.25 |

33.9 |

20.4 |

|

70 × 70 |

.0065 |

.165 |

.0078 |

.20 |

29.8 |

20.8 |

|

80 × 80 |

.0065 |

.165 |

.0060 |

.15 |

23.0 |

23.2 |

|

80 × 80 |

.0055 |

.140 |

.0070 |

.18 |

31.4 |

16.9 |

|

80 × 80 |

.0047 |

.119 |

.0078 |

.198 |

39 |

11.39 |

|

90 × 90 |

.005 |

.127 |

.0061 |

.16 |

30.1 |

15.8 |

|

100 × 100 |

.0045 |

.114 |

.0055 |

.14 |

30.3 |

14.2 |

|

100 × 100 |

.004 |

.102 |

.0060 |

.15 |

36.0 |

11.0 |

|

100 × 100 |

.0035 |

.089 |

.0065 |

.17 |

42.3 |

8.3 |

|

110 × 110 |

.0040 |

.1016 |

.0051 |

.1295 |

30.7 |

12.4 |

|

120 × 120 |

.0037 |

.0940 |

.0064 |

.1168 |

30.7 |

11.6 |

|

150 × 150 |

.0026 |

.0660 |

.0041 |

.1041 |

37.4 |

7.1 |

|

160 × 160 |

.0025 |

.0635 |

.0038 |

.0965 |

36.4 |

5.94 |

|

180 × 180 |

.0023 |

.0584 |

.0033 |

.0838 |

34.7 |

6.7 |

|

200 × 200 |

.0021 |

.0533 |

.0029 |

.0737 |

33.6 |

6.2 |

|

250 × 250 |

.0016 |

.0406 |

.0024 |

.0610 |

36.0 |

4.4 |

|

270 × 270 |

.0016 |

.0406 |

.0021 |

.0533 |

32.2 |

4.7 |

|

300 × 300 |

.0051 |

.0381 |

.0018 |

.0457 |

29.7 |

3.04 |

Regular specification table of Plain Dutch Weave Carpenter 20 filter woven wire

|

Mesh Count |

Wire Diameter. (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

8 x 85 |

.014 x .0126 |

318-340 |

250-255 |

|

12 x 64 |

.024 x .0165 |

270-285 |

200-205 |

|

14 x 88 |

.020 x .013 |

225-245 |

150-155 |

|

20 x 150 |

.0098 x .007 |

155-165 |

100-105 |

|

24 x 100 |

.015 x .010 |

115-125 |

80-85 |

|

30 x 150 |

.009 x .007 |

95-100 |

65-70 |

|

40 x 200 |

.007 x .0055 |

65-70 |

55-60 |

|

50 x 250 |

.0055 x .0045 |

55-60 |

40-45 |

Regular specification table of Twilled Dutch Weave alloy 80/20 woven wire Screens

|

Mesh Count |

Wire Diameter (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

20 x 250 |

.0098 x .0079 |

110-120 |

98-105 |

|

30 x 360 |

.0098 x .0060 |

90-100 |

80-84 |

|

40 x 560 |

.0070 x .0040 |

70-75 |

47-52 |

|

120 x 400 |

.0040 x .0025 |

50-55 |

37-43 |

|

120 x 160 |

.0040 x .0025 |

40-45 |

28-32 |

|

80 x 700 |

.0040 x .0030 |

35-40 |

24-26 |

|

200 x 600 |

.0024 x .0018 |

28-32 |

19-21 |

|

165 x 800 |

.0028 x .0020 |

24-26 |

14-16 |

|

165 x 1400 |

.0028 x .0016 |

16-18 |

9-11 |

|

200 x 1400 |

.0028 x .0016 |

12-14 |

5-6 |

|

250 x 1400 |

.0022 x .0016 |

11-12 |

3-4 |

-Residential Heating Resistance Elements.

-Industrial electric furnace heating elements

-Air heater and Water heaters.

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY