Professional Stainless Steel Wire Mesh Manufacturer and Stockist from China.

Feel free to call or email our senior sales.

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

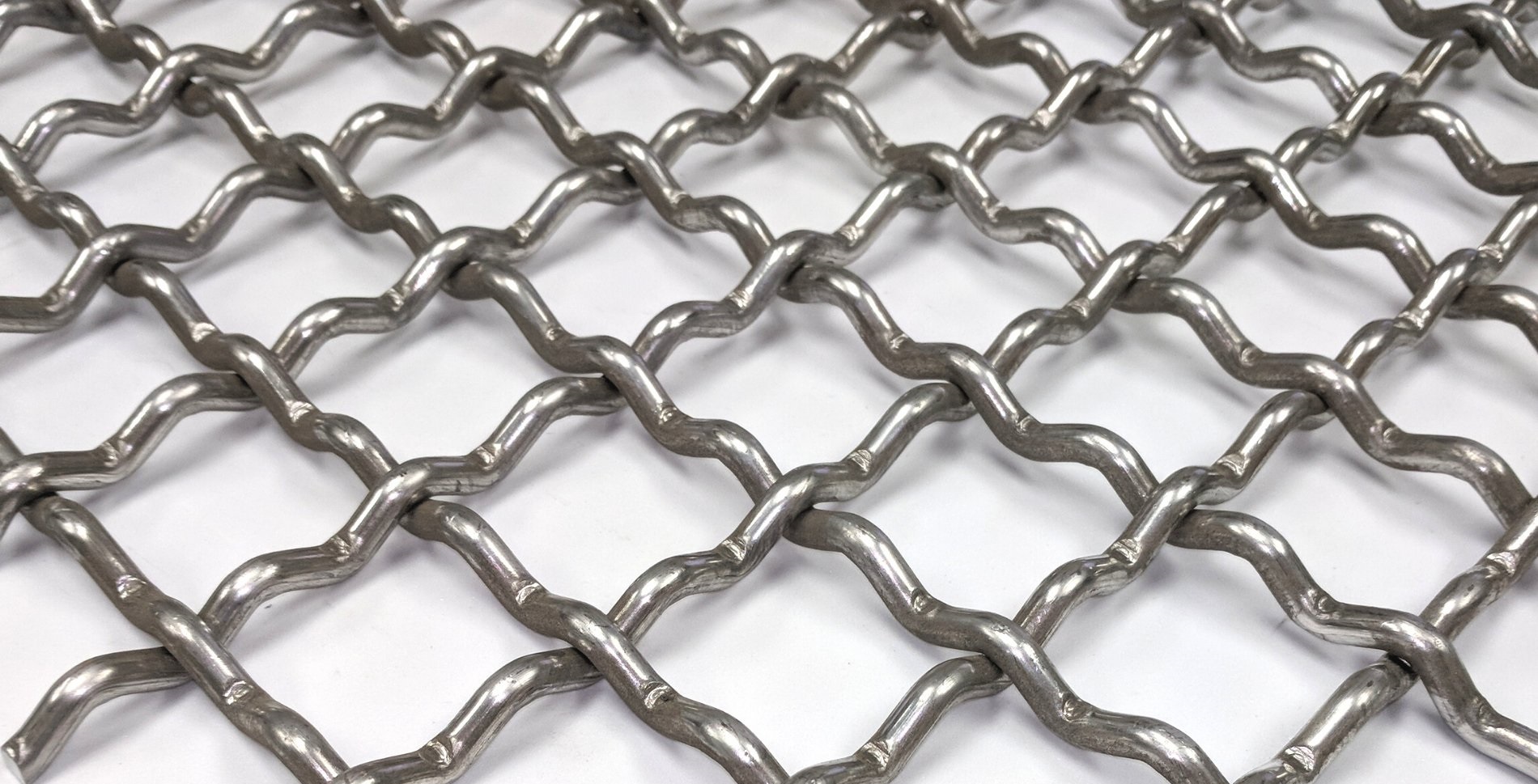

Pre-Crimped Stainless Steel Wire Mesh

Material: SS201, 302,304,304L,316,316L,310,321 and other special alloy wires

Type: Rigid Crimped Woven Wire

Patterns: Double Crimped, Lock Crimped, Inter Crimped, Flat Top Crimp

Mesh Count: 1-11Mesh and other custom-made mesh count

Wire Diameter: Custom-made wire diameters based on customers' requirement.

Width: Based on customers' requirements.

Length: Based on customers' requirements.

Pre-crimped wire mesh is a woven wire mesh that is made from pre-crimped wires. The woven wire mesh is usually made of coarse wires, which can include stainless steel, carbon steel, galvanized steel, aluminum, copper alloys, and other types of special alloy wires. However, stainless steel is the most widely used material due to its excellent weather-resistant performance.

At METART, we keep a variety of standard specifications of pre-crimped wire mesh in our warehouse as regular stock to better serve our customers. Our inventory primarily includes 304-grade and ss316 crimped wire mesh.

Pre-crimping is a process that is done prior to production. In regular woven wire mesh and wire cloth, a beaming process or endless warp wires are placed behind the machines. When the shute wires go over, across, and under every single piece of warp wire, the small crimp in the wire mesh is created by a natural force from the beat of the sley. However, crimped woven wire mesh is generally made of bigger gauge coarse wires and is a heavy-duty wire mesh product that cannot be produced directly on the machines. This is why people have developed a pre-crimping method to make it easier to weave and form the required specifications.

The pre-crimping process is usually carried out by using specially designed hard alloy-made toolings. These toolings are a pair of gear wheels that are produced based on the aperture shape and size. The wires are fed through the toolings automatically, and the required crimp is made. The pre-crimping process not only makes it easier to weave and form the specifications but also ensures a consistent and accurate crimp throughout the woven wire mesh, leading to better performance and durability.

Pre-crimped wire mesh has a wide range of applications, including in the mining, quarrying, and food industries. In the mining and quarrying industries, it is used as screening for separating materials of different sizes. In the food industry, pre-crimped wire mesh is used for sieving and separating, such as in flour sifting and grading of food products. Additionally, it can be used in architectural and decorative applications as well. With its durability, strength, and versatility, pre-crimped wire mesh is a valuable material in many industries.

Packing Details: Plastic woven Fabric, Bubble film, or craft paper based on different mesh counts. With plywood pallets or plywood cases.

Lead time: 5 days for items in stock. Custom-made specifications need to be negotiated with our sales representatives.

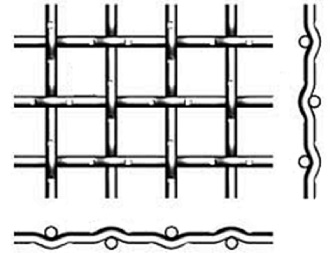

There are 4 main pre-crimped woven wire mesh patterns.

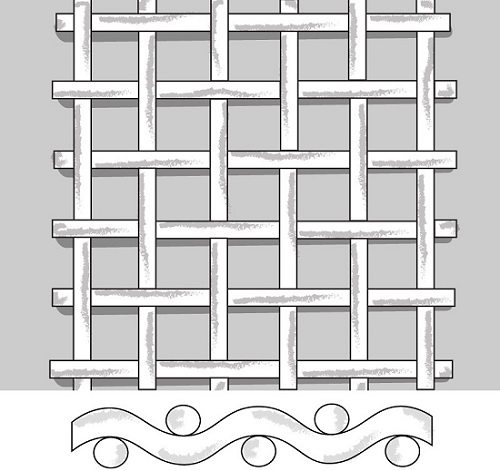

#1 Double Crimped Woven Wire Mesh Pattern

The double crimp weaving pattern, also known as the plain weave crimp pattern, appears identical to a plain weave wire mesh pattern. However, it differs from the typical plain weave  pattern. In traditional plain weave wire mesh, the wires undergo an individual pre-warping process on a warp beam. After the wires are warped, they are then threaded through the weaving heddles and reed. Once the loom is started, the shute wires are automatically fed through a pre-spooler containing a weft wire spool. Both the warp wires and shute wires are straight before being woven. During weaving, the shute wires are placed accurately through the beat of the sley where the steel reed is installed.

pattern. In traditional plain weave wire mesh, the wires undergo an individual pre-warping process on a warp beam. After the wires are warped, they are then threaded through the weaving heddles and reed. Once the loom is started, the shute wires are automatically fed through a pre-spooler containing a weft wire spool. Both the warp wires and shute wires are straight before being woven. During weaving, the shute wires are placed accurately through the beat of the sley where the steel reed is installed.

On the other hand, the double-crimp weaving wire mesh pattern uses pre-crimped wires as both the warp and shute wires. Typically, both the warp and shute wires are crimped before being cut to size for those heavy-duty wires. As a result, the beat-up movement becomes easier as the wires just need to be well placed in the crimps without applying a strong force. Meanwhile, it provides additional strength for those lightweight mesh specifications that require smaller gauged wires.

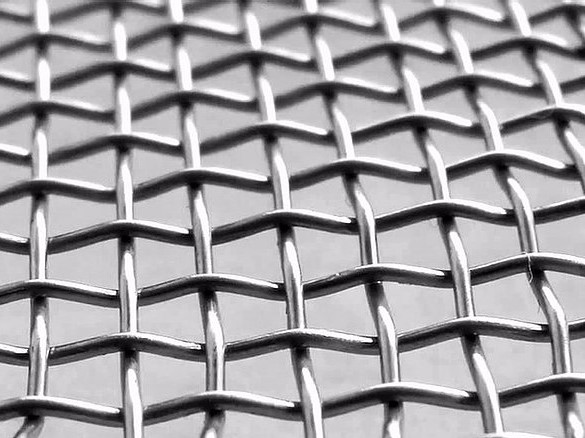

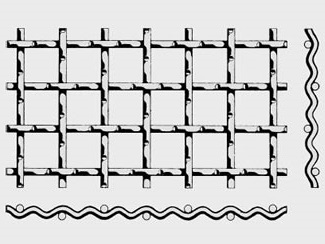

#2 Intermediate Crimped Wire Mesh Pattern

Intermediate crimped wire mesh is a versatile and commonly used type of crimped woven wire mesh. Also known as Intercrimp woven wir e mesh, multiple crimp wire mesh, and multi-crimped woven wire mesh, it is made from pre-crimped wires in both horizontal and vertical directions, which gives it excellent rigidity and stability. This unique weaving pattern allows for the creation of various hole sizes, including square and rectangular shapes.

e mesh, multiple crimp wire mesh, and multi-crimped woven wire mesh, it is made from pre-crimped wires in both horizontal and vertical directions, which gives it excellent rigidity and stability. This unique weaving pattern allows for the creation of various hole sizes, including square and rectangular shapes.

The crimped warp wires are placed at every other shute wire, giving the intermediate crimped wire mesh its characteristic pattern. This crimping arrangement offers superior strength and durability, making it an ideal choice for applications that require high structural integrity. It is widely used in industries such as construction, mining, filtration, and agriculture, where its exceptional rigidity and strength make it an ideal solution.

One of the significant advantages of intermediate crimped wire mesh is its ability to accommodate different opening sizes, which allows for the production of wire mesh with smaller diameters but larger openings. This flexibility makes it possible to create custom wire mesh products that meet the specific requirements of each application.

Intermediate crimped wire mesh is available in a range of materials, including stainless steel, carbon steel, galvanized steel, aluminum, and copper alloys. Stainless steel is the most popular material used for intermediate crimped wire mesh due to its excellent corrosion resistance and durability.

intermediate crimped wire mesh is a versatile and durable option for a wide range of applications.

Its unique weaving pattern offers excellent rigidity and stability, and its ability to accommodate different opening sizes makes it a flexible solution that can be tailored to meet the specific needs of each application.

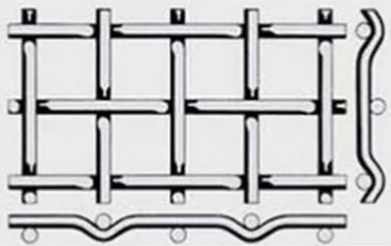

#3 Lock Crimped Wire Mesh Pattern

Lock-crimped woven wire mesh is a versatile material that is commonly used in both industrial and architectural applications. In the industrial sector, it is often used for applications such as filtering, sorting, screening, and sizing. The lock crimped pattern provides extra rigidity and strength, making it ideal for heavy-duty applications that require a durable and long-lasting material. Lock-crimped woven wire mesh is also resistant to corrosion and abrasion, making it well-suited for use in harsh environments.

In the mining industry, lock-crimped woven wire mesh is used for screening and sizing applications in ore processing plants. It is also used for safety and security applications, such as fencing and partitions. In the construction industry, lock-crimped woven wire mesh is used for reinforcing concrete, as well as for safety barriers and fencing. In addition, it is used in the food processing industry for sorting and sizing applications.

In the architectural industry, lock-crimped woven wire mesh is a popular material for both functional and aesthetic applications. It is commonly used for façade cladding, sun shading, and privacy screens. The material's strength, durability, and corrosion resistance make it well-suited for use in outdoor architectural applications. Lock-crimped woven wire mesh is also popular for interior design applications, such as room dividers, decorative panels, and feature walls. The material's unique texture and pattern can add a modern and industrial aesthetic to any space.

In addition, lock-crimped woven wire mesh can be customized to meet specific design and functional requirements. For example, some architectural applications require a smooth, mirror-like finish on the straight parts in between the crimps. This requires extra milling and finishing to achieve the desired effect.

Overall, lock-crimped woven wire mesh is a versatile and reliable material that can be used in a wide range of applications in both the industrial and architectural sectors. Its strength, durability, and aesthetic qualities make it a popular choice for designers, architects, and engineers.

#4 Flat Top Crimped Woven Wire Mesh Pattern

Flat-top crimped woven wire mesh, also known as smooth-top woven wire mesh, has a unique crimping pattern that sets it apart from other types of woven wire mesh. This pattern involves all the crimps being produced on one side of the mesh, leaving the back side completely flat an d smooth. The result is a wire mesh with a more polished appearance compared to other crimped woven wire mesh patterns.

d smooth. The result is a wire mesh with a more polished appearance compared to other crimped woven wire mesh patterns.

Due to its smooth surface, the flat-top crimped woven wire mesh is an ideal choice for applications in the quarrying and mining industry. The flat surface allows materials to pass through with less friction, making it less prone to wear and tear compared to other woven wire mesh patterns.

In addition to its industrial uses, the smooth and polished appearance of flat-top crimped woven wire mesh makes it a popular choice for architectural applications as well. It is often used in interior partition infill mesh, wall cladding decorative wire mesh, stainless steel balustrade infill wire mesh panels, building façade screen mesh, and architectural fencing infill wire mesh.

Whether it is being used for industrial or architectural purposes, flat-top crimped woven wire mesh provides excellent durability and versatility. Its unique crimping pattern makes it stand out from other types of woven wire mesh, and its smooth surface gives it a polished appearance that is favored by architects and designers.

• Sieving and Separation in Quarrying and Mining Industries:

Crimped wire mesh is widely used in the quarrying and mining industries for sieving and separation purposes. Its durable and high-strength design makes it ideal for use in tough and abrasive environments. With different crimp patterns and opening sizes available, crimped wire mesh can be tailored to suit different materials and separation requirements.

• Food Grade Stainless Steel BBQ Grilles:

The crimped wire mesh made of food-grade stainless steel is widely used as BBQ grilles due to its excellent resistance to high temperatures, rust, and corrosion. The crimped design provides better stability and rigidity compared to woven wire mesh, making it a popular choice for grilling meat, vegetables, and other food items.

• Fencing Infill Mesh Panels, Balustrading Infill Mesh, Fencing Infill Wire Mesh Panels, and Shading Screens:

Crimped wire mesh is also used in architectural and landscaping projects, such as fencing infill mesh panels, balustrading infill mesh, fencing infill wire mesh panels, and shading screens. Its unique crimp pattern and high-strength design provide excellent visibility, security, and ventilation while enhancing the aesthetics of the surrounding environment.

• Protective Guard Layer of Water Filters or Other Liquid Filters:

The crimped wire mesh can be used as a protective guard layer in water filters or other liquid filters. Its durable design can effectively prevent unwanted particles or debris from entering the filtration system, ensuring optimal filtration efficiency and protecting the filtration equipment.

• Cabinet Door Metal Grilles:

Crimped wire mesh is also widely used as cabinet door metal grilles. Its high-strength and durable design can provide excellent ventilation and protection for cabinets and other storage units. With various crimp patterns and opening sizes available, it can be customized to suit different design and functional requirements.

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY