Professional Stainless Steel Wire Mesh Manufacturer and Stockist from China.

Feel free to call or email our senior sales.

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

Pure Nickel Wire Cloth

Material: Pure Nickel 200 wire or Nickel 201 wires.

Type: Industrial exotic alloy wire mesh

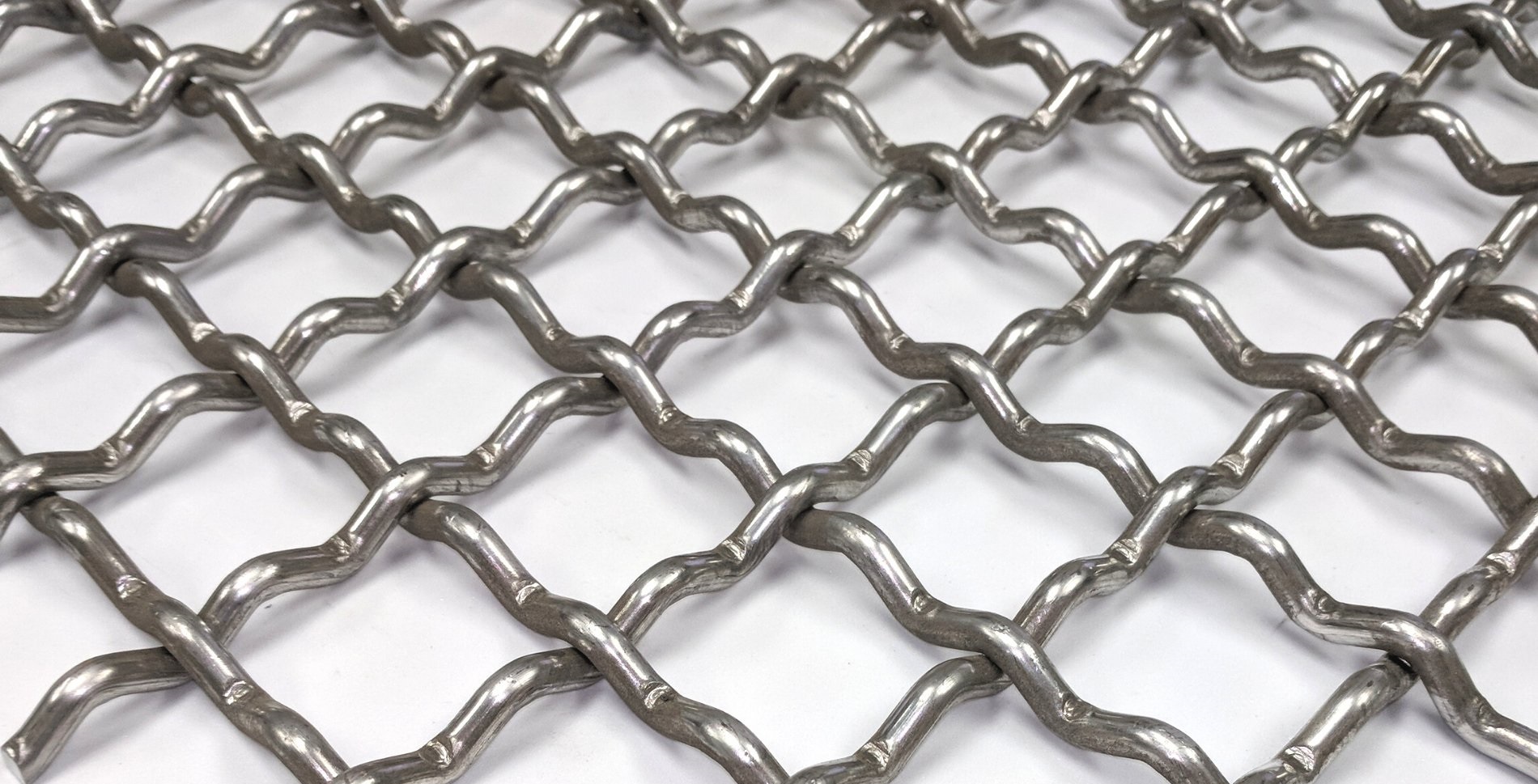

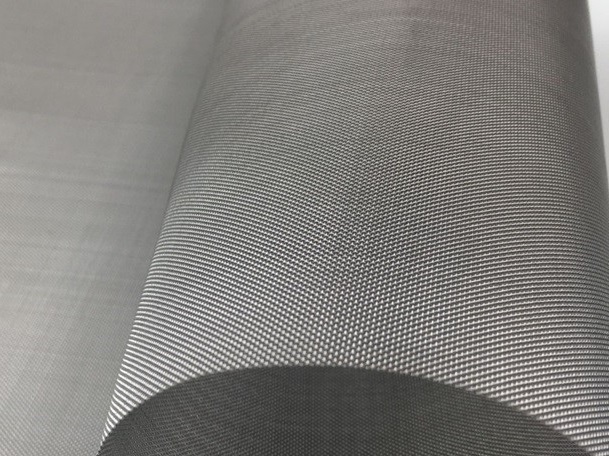

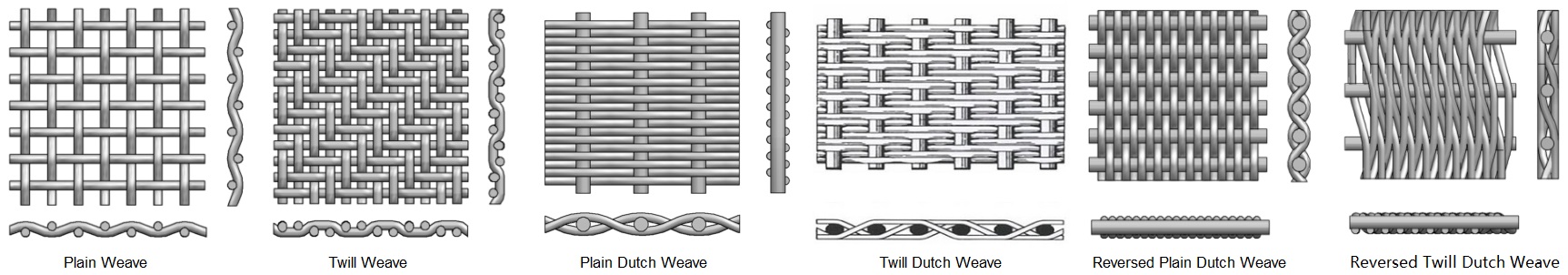

Pattern of Weave: Plain & Twill Weave, Dutch Weave, Crimped Weave.

Mesh Count: Customized.

Wire Dia.: Customized.

Roll Width: Customized.

Roll Length: standard 30 meters roll or other customized size.

Made of pure nickel wires, the nickel woven wire cloth is very malleable and ductile among all wire mesh products.

Made of pure nickel wires, the nickel woven wire cloth is very malleable and ductile among all wire mesh products.

There are two types of commonly used nickel mesh which are Ni200 mesh and Ni201 mesh. Both options are pure nickel wire meshes. In China, Ni201 has an equivalent grade of N4 and Ni200 has an equivalent of N6. Also, they have a UNS equivalent of UNS.N02200 and UNS.N02201 respectively.

The only difference between these two grades is the content of carbon elements.

Ni201 material has a relatively lower carbon content which means Ni201 filter mesh is purer than Ni200 filter mesh products.

Nickel wire mesh and wire cloth products are of great corrosion resistance, a high degree of electrical conductivity, and a very low electrical resistivity.

Advantages of Nickel 200 Wire Screen (UNS N02200)

Nickel 200 is an alloy that contains 99.6% pure nickel and may be utilized in any environment with temperatures lower than 600 degrees Fahrenheit. It has a very strong resistance to corrosion brought on by both acidic and basic salt solutions. Additionally, nickel alloy 200 exhibits low rates of corrosion in water that has been neutralized or distilled. This nickel alloy is capable of being cold or hot shaped into any shape. Additional advantages consist of the following:

-Excellent mechanical characteristics

-High conductivity both thermal and electrical in nature

-A low percentage of gases

-Very little vapor pressure

-Magnetic characteristics

Advantages of Nickel 201 Alloy (UNS N02201)

Nickel 201 alloy is a commercially pure wrought alloy with quite similar properties to nickel 200 alloy.

However, nickel 201 alloy has a reduction in carbon concentration in order to prevent embrittlement caused by intergranular carbon when the temperature is elevated. -Excellent resistance to caustic alkalis in all states, even the molten one.

-Good resistance to acids and alkalis and works best in reducing circumstances.

-Excellent caustic alkali resistance, including molten.

-Good resistance to acid, alkaline, and neutral salt solutions, but oxidizing salt solutions attack severely.

-Resistant to all dry gases at ambient temperature including dry chlorine and hydrogen chloride at 550C.

-Temperature, concentration, and aeration affect mineral acid resistance.

-Chlorates are virtually impervious to intergranular assault above 315C.

Chemical Composition of Nickel 200 and Nickel 201 Woven Wire Screens.

|

Ni+Co |

Cu % |

Si % |

Mn % |

C % |

Cr % |

S % |

Fe % |

|

|

Ni201 Mesh |

Balance |

0.25 |

0.3 Max |

0.35 Max |

0.02 Max |

0.2 Max |

0.01 Max |

0.3 Max |

|

Ni200 Mesh |

Balance |

0.25 |

0.3 Max |

0.35 Max |

0.15 Max |

0.2 |

0.01 Max |

0.3 |

Physical Properties of Nickel 200 and 201 Alloy Wire Mesh

|

Physical Property |

|

|

Density under Room temperature |

8.89 g/cm3, 0.321 lb/inch3 |

|

Young Modulus at 78℉ |

29.7 x 10(6) psi |

|

Melting temperature |

1440℃ or 2624℉ |

|

Specific heat at 70℉ |

0.109 Btu/lb-℉ |

|

Thermal conductivity at 70℉ |

487 Btu.inch/ft2.h.℉ |

|

Electrical resistivity at 70℉ |

58 ohm.cir mil/ft or 9.5Microhm-cm |

|

Specific gravity |

8.89 |

|

Temperature coefficient of resistance |

0.004/0.005 per ℃ |

|

Curie temperature |

680℉ or 360℃ |

|

Magnetic Saturation |

0.61 tesla |

|

Modulus of elasticity in tension |

30 x 10(6) osi |

Tensile Properties of Pure Nickel Alloy.

|

Cold processed |

Ultimate tensile strength |

75 ksi or 515 Mpa |

|

Yield Strength cold processed |

50 ksi or 345 Mpa |

|

|

Elongation |

15 % |

|

|

Hot processed |

Ultimate tensile strength |

55 ksi or 380 Mpa |

|

Yield Strength cold processed |

15 ksi or 105 Mpa |

|

|

Elongation |

40% |

Regular Specification Table of plain weave and twill weave nickel wire cloth

|

/Inch |

Wire Diameter |

Aperture |

Open Area % |

Weight (LB) /100 Square Foot |

||

|

Inch |

MM |

Inch |

MM |

|||

|

1 × 1 |

.080 |

2.03 |

.920 |

23.37 |

84.6 |

41.1 |

|

2 × 2 |

.063 |

1.60 |

.437 |

11.10 |

76.4 |

51.2 |

|

3 × 3 |

.054 |

1.37 |

.279 |

7.09 |

70.1 |

56.7 |

|

4 × 4 |

.063 |

1.60 |

.187 |

4.75 |

56.0 |

104.8 |

|

4 × 4 |

.047 |

1.19 |

.203 |

5.16 |

65.9 |

57.6 |

|

5 × 5 |

.041 |

1.04 |

.159 |

4.04 |

63.2 |

54.9 |

|

6 × 6 |

.035 |

.89 |

.132 |

3.35 |

62.7 |

48.1 |

|

8 × 8 |

.028 |

.71 |

.097 |

2.46 |

60.2 |

41.1 |

|

10 × 10 |

.025 |

.64 |

.075 |

1.91 |

56.3 |

41.2 |

|

10 × 10 |

.020 |

.51 |

.080 |

2.03 |

64.0 |

26.1 |

|

12 × 12 |

.023 |

.584 |

.060 |

1.52 |

51.8 |

42.2 |

|

12 × 12 |

.020 |

.508 |

.063 |

1.60 |

57.2 |

31.6 |

|

14 × 14 |

.023 |

.584 |

.048 |

1.22 |

45.2 |

49.8 |

|

14 × 14 |

.020 |

.508 |

.051 |

1.30 |

51.0 |

37.2 |

|

16 × 16 |

.018 |

.457 |

.0445 |

1.13 |

50.7 |

34.5 |

|

18 × 18 |

.017 |

.432 |

.0386 |

.98 |

48.3 |

34.8 |

|

20 × 20 |

.020 |

.508 |

.0300 |

.76 |

36.0 |

55.2 |

|

20 × 20 |

.016 |

.406 |

.0340 |

.86 |

46.2 |

34.4 |

|

24 × 24 |

.014 |

.356 |

.0277 |

.70 |

44.2 |

31.8 |

|

30 × 30 |

.013 |

.330 |

.0203 |

.52 |

37.1 |

34.8 |

|

30 × 30 |

.012 |

.305 |

.0213 |

.54 |

40.8 |

29.4 |

|

30 × 30 |

.009 |

.229 |

.0243 |

.62 |

53.1 |

16.1 |

|

35 × 35 |

.011 |

.279 |

.0176 |

.45 |

37.9 |

29.0 |

|

40 × 40 |

.010 |

.254 |

.0150 |

.38 |

36.0 |

27.6 |

|

50 × 50 |

.009 |

.229 |

.0110 |

.28 |

30.3 |

28.4 |

|

50 × 50 |

.008 |

.203 |

.0120 |

.31 |

36.0 |

22.1 |

|

60 × 60 |

.0075 |

.191 |

.0092 |

.23 |

30.5 |

23.7 |

|

60 × 60 |

.007 |

.178 |

.0097 |

.25 |

33.9 |

20.4 |

|

70 × 70 |

.0065 |

.165 |

.0078 |

.20 |

29.8 |

20.8 |

|

80 × 80 |

.0065 |

.165 |

.0060 |

.15 |

23.0 |

23.2 |

|

80 × 80 |

.0055 |

.140 |

.0070 |

.18 |

31.4 |

16.9 |

|

80 × 80 |

.0047 |

.119 |

.0078 |

.198 |

39 |

11.39 |

|

90 × 90 |

.005 |

.127 |

.0061 |

.16 |

30.1 |

15.8 |

|

100 × 100 |

.0045 |

.114 |

.0055 |

.14 |

30.3 |

14.2 |

|

100 × 100 |

.004 |

.102 |

.0060 |

.15 |

36.0 |

11.0 |

|

100 × 100 |

.0035 |

.089 |

.0065 |

.17 |

42.3 |

8.3 |

|

110 × 110 |

.0040 |

.1016 |

.0051 |

.1295 |

30.7 |

12.4 |

|

120 × 120 |

.0037 |

.0940 |

.0064 |

.1168 |

30.7 |

11.6 |

|

150 × 150 |

.0026 |

.0660 |

.0041 |

.1041 |

37.4 |

7.1 |

|

160 × 160 |

.0025 |

.0635 |

.0038 |

.0965 |

36.4 |

5.94 |

|

180 × 180 |

.0023 |

.0584 |

.0033 |

.0838 |

34.7 |

6.7 |

|

200 × 200 |

.0021 |

.0533 |

.0029 |

.0737 |

33.6 |

6.2 |

Regular specification table of Plain Dutch Weave Pure Nickel Wire Mesh

|

Mesh Count |

Wire Diameter. (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

8 x 85 |

.014 x .0126 |

318-340 |

250-255 |

|

12 x 64 |

.024 x .0165 |

270-285 |

200-205 |

|

14 x 88 |

.020 x .013 |

225-245 |

150-155 |

|

20 x 150 |

.0098 x .007 |

155-165 |

100-105 |

|

24 x 100 |

.015 x .010 |

115-125 |

80-85 |

|

30 x 150 |

.009 x .007 |

95-100 |

65-70 |

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY