Professional Stainless Steel Wire Mesh Manufacturer and Stockist from China.

Feel free to call or email our senior sales.

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

Duplex and Super Duplex Stainless Steel Wire Mesh

Material: Duplex Stainless Steel wires and Super duplex stainless steel wires.

Type: Industrial Exotic Wire Mesh

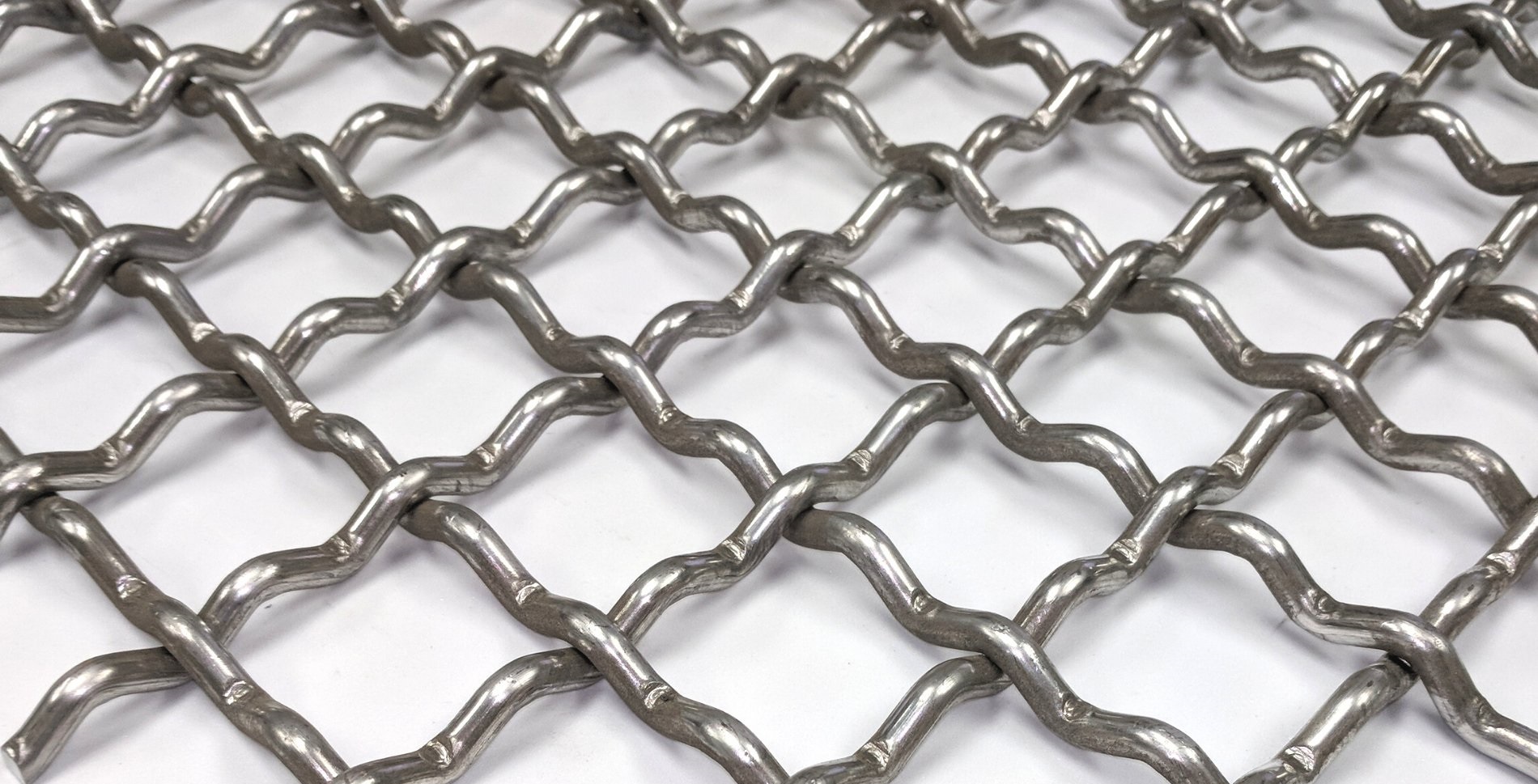

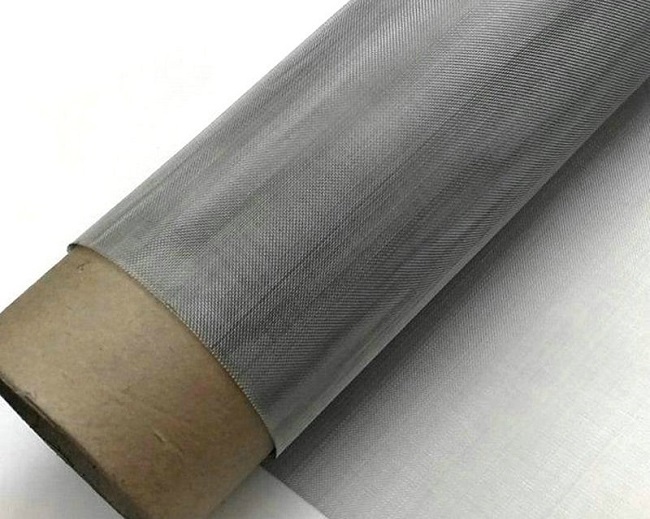

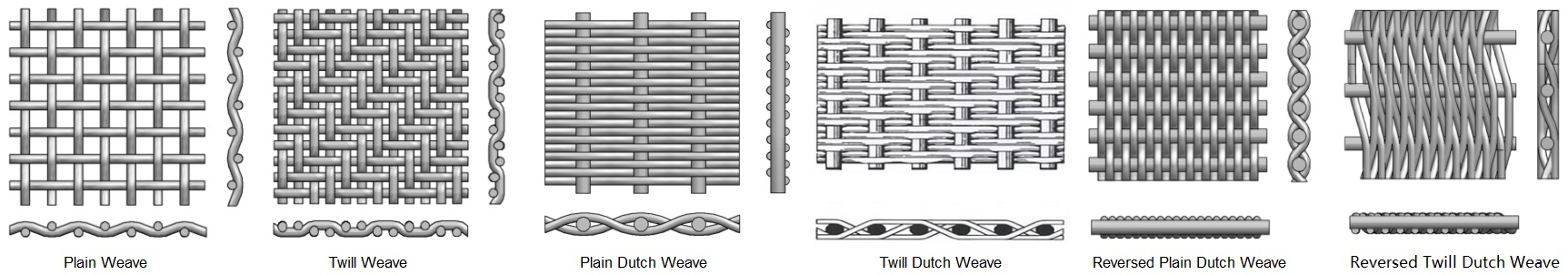

Patterns of Weave: Plain & Twill Weave, Dutch Weave, Crimped Weave.

Mesh Count: Customized.

Wire Dia.: Customized.

Roll Width: Customized sizes.

Roll Length: Standard 30 meters roll and other cutomized sizes.

METART Duplex Stainless Steel Wire Mesh family has three different types, including Duplex 2205 wire mesh, SAF 2205 wire mesh, and super duplex 2507 wire mesh. METART mainly produce duplex in a woven way, but we can also customize welded duplex stainless steel wires based on customers’ requirements.

METART Duplex Stainless Steel Wire Mesh family has three different types, including Duplex 2205 wire mesh, SAF 2205 wire mesh, and super duplex 2507 wire mesh. METART mainly produce duplex in a woven way, but we can also customize welded duplex stainless steel wires based on customers’ requirements.

Duplex 2205 Wire Mesh and Wire Cloth.

Duplex 2205 woven wire mesh is also referred to as its UNS equivalent S31803 or W.Nr 1.4462 wire mesh which is basically made of a nitrogen-enhanced duplex stainless steel that was created to overcome the prevalent corrosion issues of the 300 series stainless steels.

"Duplex" refers to a family of stainless steels that are neither entirely austenitic nor purely ferritic, like 304 stainless or 430 stainless, respectively. Duplex stainless steel 2205 is composed of austenite pools surrounded by a continuous ferrite phase. In its annealed state, 2205 includes between 40 and 50% ferrite. 2205 is the most often used grade in the duplex family of stainless steels.

The benefit of a duplex structure is that it combines the advantageous characteristics of a ferritic alloy (resistance to stress corrosion cracking and high strength) with those of an austenitic alloy (ease of fabrication and corrosion resistance).

The Using 2205 Duplex stainless steel should be controlled under temperatures of 600℉. And extended exposure to elevated temperatures can cause 2205 stainless steel to become brittle.

SAF 2205® Wire Mesh and Wire Cloth

SAF 2205 stainless steel is the trademark of Sandvik. SAF 2205 filter mesh is also known as UNS.S32205 wire mesh.

Both UNS.S32205 and UNS.S31803 grade stainless steel specifications were initially collected as UNS S31803. However, a lot of the main producers routinely produced this grade at the limit of the specification's tolerance. This was a result of their effort to optimize the corrosion resistance of the alloy, supported by the invention of the AOD steelmaking process, which allowed for greater compositional control.

In addition, it enabled the level of nitrogen additions to be controlled, as opposed to simply being a background feature. Therefore, the highest-performing duplex grade aimed to optimize chromium (Cr), molybdenum (Mo), and nitrogen concentrations (N). Based on the formula PREN = %Cr + 3.3%Mo + 16% N, the difference between a duplex stainless steel alloy whose composition meets the bottom of the criteria and one that meets the top value of the specification.

To distinguish the duplex stainless steel manufactured at the upper end of the composition range, the UNS S32205 specification was created. The S32205 (F60) specification fully satisfies the S31803 (F51) specification, however, the contrary is not true. Therefore S32205 is eligible for dual certification as S31803.

Duplex S32205 provides better-guaranteed corrosion resistance, however, the majority of the already manufactured Duplex S31803 also conforms to Duplex S32205.

Due to the precipitation of brittle micro components at temperatures above 300 °C and the change from ductile to brittle at temperatures below -50 °C, 2205 filter mesh products are generally unsuitable for usage at these temperatures.

|

EQUIVALENT STANDARDS OF DUPLEX STAINLESS STEEL MESH |

||||

|

INDUSTEEL TRADEMARKS |

UNS |

UNS |

EURONORMS EN |

SUS |

|

DUPLEX STAINLESS STEEL MESH |

S31803 |

S32205 |

1.4462 |

SUS 329J3L |

Chemical composition of UNS.S31803 and UNS.S32205 filter mesh:

|

|

C % |

Mn % |

Si % |

P % |

S % |

Cr % |

Mo % |

Ni % |

N % |

|

2205 |

0.03 |

2 |

1 |

0.03 |

0.02 |

min21.0 |

min2.5 |

min4.5 |

min0.08 |

|

max |

max |

max |

max |

max |

max23.0 |

max3.5 |

max6.5 |

max0.20 |

|

|

2205 |

0.03 |

2 |

1 |

0.03 |

0.02 |

min22.0 |

min3.0 |

min4.5 |

min0.14 |

|

max |

max |

max |

max |

max |

max23.0 |

max3.5 |

max6.5 |

max0.20 |

Mechanical Properties of duplex stainless filter screens:

|

Grade |

Tensile Strength |

Yield Strength |

Elongation % |

Hardness (HB) |

|

Duplex 2205 |

90 |

65 |

25 |

217 |

Physical Properties:

|

Condition |

Density |

Electrical |

Thermal |

Heat Capacity |

Electrical |

|

@ 68°F |

0.278 |

27.6 |

8.7 |

0.112 |

33.5 |

|

@ 212°F |

|

26.1 |

9.2 |

0.119 |

35.4 |

|

@ 392°F |

|

25.4 |

9.8 |

0.127 |

37.4 |

|

@ 572°F |

|

24.9 |

10.4 |

0.134 |

39.4 |

Super Duplex Stainless Steel Wire Mesh and Wire Cloth.

Super duplex stainless steel wire mesh is also well known by its UNS name or its W.Nr equivalent 1.4410 wire mesh. It is also simply called alloy 2507 filter mesh.

It is made of quality super duplex stainless steel wires that have both ferritic and austenitic grades.

With around 25% of chromium, 4% of molybdenum, and 7% nickel elements, this super duplex stainless steel alloy mesh is designed for applications that demand exceptional strength and corrosion resistance.

This high molybdenum, chromium, and nitrogen concentration provide 2507 stainless steel with outstanding resistance to chloride stress corrosion cracking.

Duplex 2507 stainless steel filter screens should only be used in temperatures below 316° C (600° F). Extended exposure to elevated temperatures can weaken the alloy 2507's hardness and corrosion resistance.

Duplex 2507 stainless steel wires and mesh products also possess outstanding mechanical qualities.

Typically, a thin gauge of 2507 wire material can reach the same strength as a heavier nickel alloy. The consequent weight reduction can significantly reduce the total cost of manufacture.

Features of Super Duplex Stainless Steel Filter Mesh

-Superior resistance to chloride stress cracking

-High Strength

-Excellent resistance to chloride pitting and crevice corrosion

-Good general corrosion resistance

-Recommended for use in applications up to 600°F

-The low thermal expansion rate

-Combination of austenitic and ferritic structural characteristics

-Good weldability and machinability

-ASME Approval for Pressure Vessel application

|

EQUIVALENT STANDARDS OF SUPER DUPLEX STAINLESS STEEL MESH |

|||||

|

INDUSTEEL TRADEMARKS |

UNS |

ASTM |

EURONORMS EN |

SUS |

|

|

SUPER DUPLEX 2507 |

S32750 |

2507 |

1.4410 |

- |

|

|

CHEMICAL COMPOSITION OF SUPER DUPLEX 2507 STAINLESS STEEL FILTER SCREEN |

|||||

|

C |

Cr |

Ni |

Mo |

N |

Others |

|

< 0,030 |

25 |

7 |

3,5 |

0,27 |

|

Mechanical Properties of 2507 super duplex wire mesh

|

Temper |

Annealed |

|

Tensile Rm |

115 ksi (min) |

|

Tensile Rm |

800 MPa (min) |

|

R.p. 0.2% Yield |

80 ksi (min) |

|

R.p. 0.2% Yield |

550 MPa (min) |

|

Elongation (2” or 4D gl) |

15% (min) |

Physical Properties of 2507 super duplex filter mes at Room Temperature)

|

Annealed |

|

|

Specific Heat (0-100°C) |

500 J.kg-1.°K-1 |

|

Thermal Conductivity |

15 W.m -1.°K-1 |

|

Thermal Expansion |

11 μm/μm/°C |

|

Modulus Elasticity |

200 GPa |

|

Electrical Resistivity |

8.12 μohm/cm |

|

Density |

7.8 g/cm3 |

Regular Specification Table of plain weave and twill weave duplex and super duplex alloy filter mesh

|

Mesh/Inch |

Wire Dia. |

Aperture Size |

Open Area % |

Weight (LB) /100 Square Foot |

||

|

Inch |

MM |

Inch |

MM |

|||

|

1 × 1 |

.080 |

2.03 |

.920 |

23.37 |

84.6 |

41.1 |

|

2 × 2 |

.063 |

1.60 |

.437 |

11.10 |

76.4 |

51.2 |

|

3 × 3 |

.054 |

1.37 |

.279 |

7.09 |

70.1 |

56.7 |

|

4 × 4 |

.063 |

1.60 |

.187 |

4.75 |

56.0 |

104.8 |

|

4 × 4 |

.047 |

1.19 |

.203 |

5.16 |

65.9 |

57.6 |

|

5 × 5 |

.041 |

1.04 |

.159 |

4.04 |

63.2 |

54.9 |

|

6 × 6 |

.035 |

.89 |

.132 |

3.35 |

62.7 |

48.1 |

|

8 × 8 |

.028 |

.71 |

.097 |

2.46 |

60.2 |

41.1 |

|

10 × 10 |

.025 |

.64 |

.075 |

1.91 |

56.3 |

41.2 |

|

10 × 10 |

.020 |

.51 |

.080 |

2.03 |

64.0 |

26.1 |

|

12 × 12 |

.023 |

.584 |

.060 |

1.52 |

51.8 |

42.2 |

|

12 × 12 |

.020 |

.508 |

.063 |

1.60 |

57.2 |

31.6 |

|

14 × 14 |

.023 |

.584 |

.048 |

1.22 |

45.2 |

49.8 |

|

14 × 14 |

.020 |

.508 |

.051 |

1.30 |

51.0 |

37.2 |

|

16 × 16 |

.018 |

.457 |

.0445 |

1.13 |

50.7 |

34.5 |

|

18 × 18 |

.017 |

.432 |

.0386 |

.98 |

48.3 |

34.8 |

|

20 × 20 |

.020 |

.508 |

.0300 |

.76 |

36.0 |

55.2 |

|

20 × 20 |

.016 |

.406 |

.0340 |

.86 |

46.2 |

34.4 |

|

24 × 24 |

.014 |

.356 |

.0277 |

.70 |

44.2 |

31.8 |

|

30 × 30 |

.013 |

.330 |

.0203 |

.52 |

37.1 |

34.8 |

|

30 × 30 |

.012 |

.305 |

.0213 |

.54 |

40.8 |

29.4 |

|

30 × 30 |

.009 |

.229 |

.0243 |

.62 |

53.1 |

16.1 |

|

35 × 35 |

.011 |

.279 |

.0176 |

.45 |

37.9 |

29.0 |

|

40 × 40 |

.010 |

.254 |

.0150 |

.38 |

36.0 |

27.6 |

|

50 × 50 |

.009 |

.229 |

.0110 |

.28 |

30.3 |

28.4 |

|

50 × 50 |

.008 |

.203 |

.0120 |

.31 |

36.0 |

22.1 |

|

60 × 60 |

.0075 |

.191 |

.0092 |

.23 |

30.5 |

23.7 |

|

60 × 60 |

.007 |

.178 |

.0097 |

.25 |

33.9 |

20.4 |

|

70 × 70 |

.0065 |

.165 |

.0078 |

.20 |

29.8 |

20.8 |

|

80 × 80 |

.0065 |

.165 |

.0060 |

.15 |

23.0 |

23.2 |

|

80 × 80 |

.0055 |

.140 |

.0070 |

.18 |

31.4 |

16.9 |

|

80 × 80 |

.0047 |

.119 |

.0078 |

.198 |

39 |

11.39 |

|

90 × 90 |

.005 |

.127 |

.0061 |

.16 |

30.1 |

15.8 |

|

100 × 100 |

.0045 |

.114 |

.0055 |

.14 |

30.3 |

14.2 |

|

100 × 100 |

.004 |

.102 |

.0060 |

.15 |

36.0 |

11.0 |

|

100 × 100 |

.0035 |

.089 |

.0065 |

.17 |

42.3 |

8.3 |

|

110 × 110 |

.0040 |

.1016 |

.0051 |

.1295 |

30.7 |

12.4 |

|

120 × 120 |

.0037 |

.0940 |

.0064 |

.1168 |

30.7 |

11.6 |

|

150 × 150 |

.0026 |

.0660 |

.0041 |

.1041 |

37.4 |

7.1 |

|

160 × 160 |

.0025 |

.0635 |

.0038 |

.0965 |

36.4 |

5.94 |

|

180 × 180 |

.0023 |

.0584 |

.0033 |

.0838 |

34.7 |

6.7 |

|

200 × 200 |

.0021 |

.0533 |

.0029 |

.0737 |

33.6 |

6.2 |

|

250 × 250 |

.0016 |

.0406 |

.0024 |

.0610 |

36.0 |

4.4 |

|

270 × 270 |

.0016 |

.0406 |

.0021 |

.0533 |

32.2 |

4.7 |

|

300 × 300 |

.0051 |

.0381 |

.0018 |

.0457 |

29.7 |

3.04 |

Regular specification table of Plain Dutch Weave duplex and Duper Duplex woven wire screens.

|

Mesh Count |

Wire Diameter. (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

8 x 85 |

.014 x .0126 |

318-340 |

250-255 |

|

12 x 64 |

.024 x .0165 |

270-285 |

200-205 |

|

14 x 88 |

.020 x .013 |

225-245 |

150-155 |

|

20 x 150 |

.0098 x .007 |

155-165 |

100-105 |

|

24 x 100 |

.015 x .010 |

115-125 |

80-85 |

|

30 x 150 |

.009 x .007 |

95-100 |

65-70 |

|

40 x 200 |

.007 x .0055 |

65-70 |

55-60 |

|

50 x 250 |

.0055 x .0045 |

55-60 |

40-45 |

Regular specification table of Twilled Dutch Weave Carpenter super duplex and duplex filter screens

|

Mesh Count |

Wire Diameter (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

20 x 250 |

.0098 x .0079 |

110-120 |

98-105 |

|

30 x 360 |

.0098 x .0060 |

90-100 |

80-84 |

|

40 x 560 |

.0070 x .0040 |

70-75 |

47-52 |

|

120 x 400 |

.0040 x .0025 |

50-55 |

37-43 |

|

120 x 160 |

.0040 x .0025 |

40-45 |

28-32 |

|

80 x 700 |

.0040 x .0030 |

35-40 |

24-26 |

|

200 x 600 |

.0024 x .0018 |

28-32 |

19-21 |

|

165 x 800 |

.0028 x .0020 |

24-26 |

14-16 |

|

165 x 1400 |

.0028 x .0016 |

16-18 |

9-11 |

|

200 x 1400 |

.0028 x .0016 |

12-14 |

5-6 |

-Filter screens in seawater systems, marine, and other high chloride environments.

-Screen filters for chemical process vessels,chemical transporting, and storage.

-Food processing equipment wire mesh parts.

-Oil field piping, Oil and gas exploration, and processing equipment.

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY