Professional Stainless Steel Wire Mesh Manufacturer and Stockist from China.

Feel free to call or email our senior sales.

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

Alloy 347 Wire Mesh

Material: alloy 347 stainless steel wires

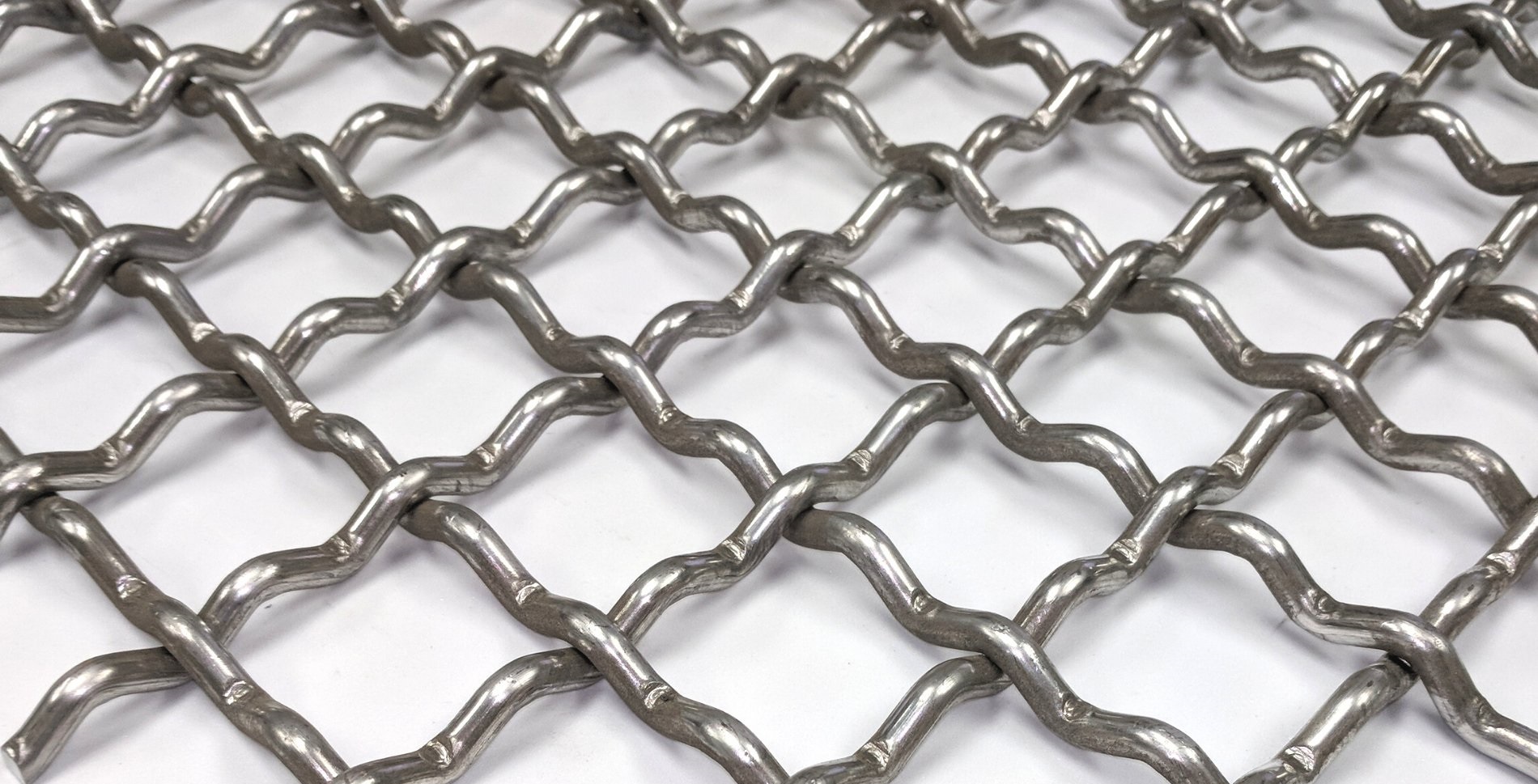

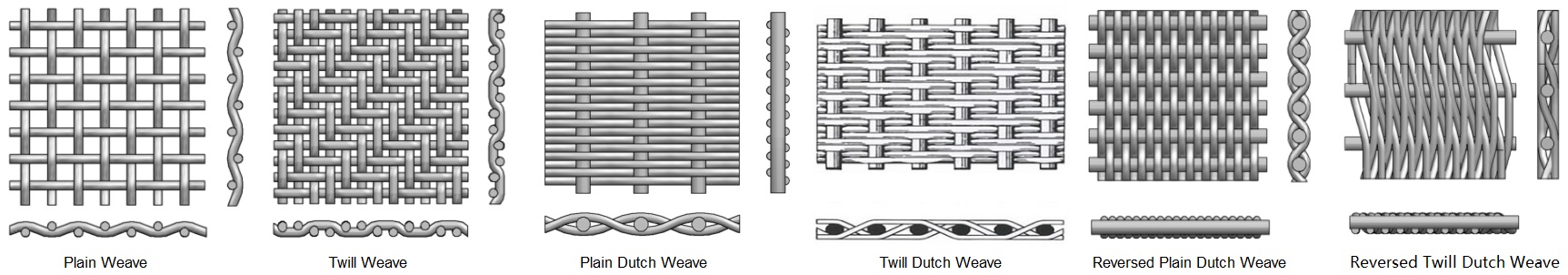

Type: Industrial exotic wire mesh

Pattern of Weave: Plain and Twill Weave, Dutch Weave, Crimped Weave.

Mesh Count: Customized.

Wire Dia.: Customized.

Roll Width: Customized size.

Roll Length: standard 30 meters rolls or other customized size.

Alloy 347 filter mesh is also referred to as its UNS designation UNS.S34700 wire mesh which is a columbium(niobium)/tantalum stabilized austenitic chromium-nickel stainless steel wire mesh screen designed to give an 18/8-type alloy with enhanced intergranular-corrosion resistance.

Alloy 347 filter mesh is also referred to as its UNS designation UNS.S34700 wire mesh which is a columbium(niobium)/tantalum stabilized austenitic chromium-nickel stainless steel wire mesh screen designed to give an 18/8-type alloy with enhanced intergranular-corrosion resistance.

As a result of the combination of columbium (niobium) and tantalum, Alloy 347 filter wire mesh has somewhat better corrosion resistance in highly oxidizing settings compared to other stainless steel alloys. Instead of developing at the grain borders, columbium-tantalum carbides precipitate inside the grains. Consider Type 347 wire mesh for applications needing intermittent heating between 800°F (427℃) and 1650°F (899℃) or for welding under conditions that exclude a post-weld anneal.

Because of its great mechanical strength and resistance to corrosion, alloy 347 stainless steel wire mesh products are especially useful for applications in which they must be exposed to high temperatures. While Alloy 304 and, more specifically, Alloy 304L may also be considered for exposures where sensitization and intergranular corrosion are issues, Alloy 347 stainless steel mesh offers higher creep and stress rupture qualities.

There are some similarities and differences between alloy 321 and alloy 347 wire mesh. In most cases, the properties of 321 stainless steel and 347 stainless steel wire mesh are similar. 321 stainless steel mesh is a type of titanium–stabilization of 18/8 austenitic stainless steel 304 wire mesh; a small number of titanium places it in the carbide precipitation temperature range, i.e., 425-850°C; intergranular corrosion does not appear after heating; it has high strength, oxidation peeling resistance, and aqueous corrosion resistance.

The 321H is a high-carbon variant of the 321 with increased high-temperature strength and is generally utilized for situations involving temperatures around 900°C. Titanium's poor welding arc transition renders 321 unsuitable for use as a welding material, but 347 wire mesh containing niobium serves the role of carbide stabilization and may also be transmitted through the welding arc. 347 is the typical material for welding 321 stainless steel and is occasionally used as the base metal.

|

EQUIVALENT STANDARDS OF ALLOY 347 WIRE MESH |

||||

|

INDUSTEEL TRADEMARKS |

UNS |

ASTM/AISI |

EURONORMS EN |

SUS |

|

… |

UNS.S34700 WIRE MESH |

347 WIRE MESH |

1.4550 WIRE MESH |

347 WIRE MESH |

Chemical Composition of SS347 wire mesh

|

Cr % |

Ni % |

C % |

Si % |

Mn % |

P % |

S % |

NB % |

Fe |

|

17.0-19 |

9.0-12 |

0.08Max |

0.75Max |

2Max |

0.045Max |

0.03Max |

10x(C+N)- 1.10 |

Balance |

Physical Properties of Alloy 347 Stainless Steel Wire Mesh

|

Physical Property |

|

|

Density |

7.96 g/cm3, 0.288 lbs/in3 |

|

Thermal Conductivity 200°F (100°C) |

16.3 W/m-°K,133 BTU/hr/ft2/ft/°F |

|

Specific Heat |

500 J/kg-°K (0–100°C), 0.12 BTU/lb-°F (32–212°F) |

|

Melting Range |

2550–2635°F |

|

Modulus of Elasticity |

28.0 x 106 psi, 193 Gpa |

|

Electrical Resistivity |

72 Microhm-cm at 20°F |

Regular Specification Table of plain weave and twill weave alloy 347 wire mesh

|

/Inch |

Wire Diameter |

Aperture |

Open Area % |

Weight (LB) /100 Square Foot |

||

|

Inch |

MM |

Inch |

MM |

|||

|

1 × 1 |

.080 |

2.03 |

.920 |

23.37 |

84.6 |

41.1 |

|

2 × 2 |

.063 |

1.60 |

.437 |

11.10 |

76.4 |

51.2 |

|

3 × 3 |

.054 |

1.37 |

.279 |

7.09 |

70.1 |

56.7 |

|

4 × 4 |

.063 |

1.60 |

.187 |

4.75 |

56.0 |

104.8 |

|

4 × 4 |

.047 |

1.19 |

.203 |

5.16 |

65.9 |

57.6 |

|

5 × 5 |

.041 |

1.04 |

.159 |

4.04 |

63.2 |

54.9 |

|

6 × 6 |

.035 |

.89 |

.132 |

3.35 |

62.7 |

48.1 |

|

8 × 8 |

.028 |

.71 |

.097 |

2.46 |

60.2 |

41.1 |

|

10 × 10 |

.025 |

.64 |

.075 |

1.91 |

56.3 |

41.2 |

|

10 × 10 |

.020 |

.51 |

.080 |

2.03 |

64.0 |

26.1 |

|

12 × 12 |

.023 |

.584 |

.060 |

1.52 |

51.8 |

42.2 |

|

12 × 12 |

.020 |

.508 |

.063 |

1.60 |

57.2 |

31.6 |

|

14 × 14 |

.023 |

.584 |

.048 |

1.22 |

45.2 |

49.8 |

|

14 × 14 |

.020 |

.508 |

.051 |

1.30 |

51.0 |

37.2 |

|

16 × 16 |

.018 |

.457 |

.0445 |

1.13 |

50.7 |

34.5 |

|

18 × 18 |

.017 |

.432 |

.0386 |

.98 |

48.3 |

34.8 |

|

20 × 20 |

.020 |

.508 |

.0300 |

.76 |

36.0 |

55.2 |

|

20 × 20 |

.016 |

.406 |

.0340 |

.86 |

46.2 |

34.4 |

|

24 × 24 |

.014 |

.356 |

.0277 |

.70 |

44.2 |

31.8 |

|

30 × 30 |

.013 |

.330 |

.0203 |

.52 |

37.1 |

34.8 |

|

30 × 30 |

.012 |

.305 |

.0213 |

.54 |

40.8 |

29.4 |

|

30 × 30 |

.009 |

.229 |

.0243 |

.62 |

53.1 |

16.1 |

|

35 × 35 |

.011 |

.279 |

.0176 |

.45 |

37.9 |

29.0 |

|

40 × 40 |

.010 |

.254 |

.0150 |

.38 |

36.0 |

27.6 |

|

50 × 50 |

.009 |

.229 |

.0110 |

.28 |

30.3 |

28.4 |

|

50 × 50 |

.008 |

.203 |

.0120 |

.31 |

36.0 |

22.1 |

|

60 × 60 |

.0075 |

.191 |

.0092 |

.23 |

30.5 |

23.7 |

|

60 × 60 |

.007 |

.178 |

.0097 |

.25 |

33.9 |

20.4 |

|

70 × 70 |

.0065 |

.165 |

.0078 |

.20 |

29.8 |

20.8 |

|

80 × 80 |

.0065 |

.165 |

.0060 |

.15 |

23.0 |

23.2 |

|

80 × 80 |

.0055 |

.140 |

.0070 |

.18 |

31.4 |

16.9 |

|

80 × 80 |

.0047 |

.119 |

.0078 |

.198 |

39 |

11.39 |

|

90 × 90 |

.005 |

.127 |

.0061 |

.16 |

30.1 |

15.8 |

|

100 × 100 |

.0045 |

.114 |

.0055 |

.14 |

30.3 |

14.2 |

|

100 × 100 |

.004 |

.102 |

.0060 |

.15 |

36.0 |

11.0 |

|

100 × 100 |

.0035 |

.089 |

.0065 |

.17 |

42.3 |

8.3 |

|

110 × 110 |

.0040 |

.1016 |

.0051 |

.1295 |

30.7 |

12.4 |

|

120 × 120 |

.0037 |

.0940 |

.0064 |

.1168 |

30.7 |

11.6 |

|

150 × 150 |

.0026 |

.0660 |

.0041 |

.1041 |

37.4 |

7.1 |

|

160 × 160 |

.0025 |

.0635 |

.0038 |

.0965 |

36.4 |

5.94 |

|

180 × 180 |

.0023 |

.0584 |

.0033 |

.0838 |

34.7 |

6.7 |

|

200 × 200 |

.0021 |

.0533 |

.0029 |

.0737 |

33.6 |

6.2 |

Regular specification table of Plain Dutch Weave 347 stainless steel woven wire

|

Mesh Count |

Wire Diameter. (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

8 x 85 |

.014 x .0126 |

318-340 |

250-255 |

|

12 x 64 |

.024 x .0165 |

270-285 |

200-205 |

|

14 x 88 |

.020 x .013 |

225-245 |

150-155 |

|

20 x 150 |

.0098 x .007 |

155-165 |

100-105 |

|

24 x 100 |

.015 x .010 |

115-125 |

80-85 |

|

30 x 150 |

.009 x .007 |

95-100 |

65-70 |

|

40 x 200 |

.007 x .0055 |

65-70 |

55-60 |

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY