Professional Stainless Steel Wire Mesh Manufacturer and Stockist from China.

Feel free to call or email our senior sales.

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

904L Wire Mesh

Material: 904L Stainless Steel Wires

Type: Industrial Exotic Alloy Wire Mesh

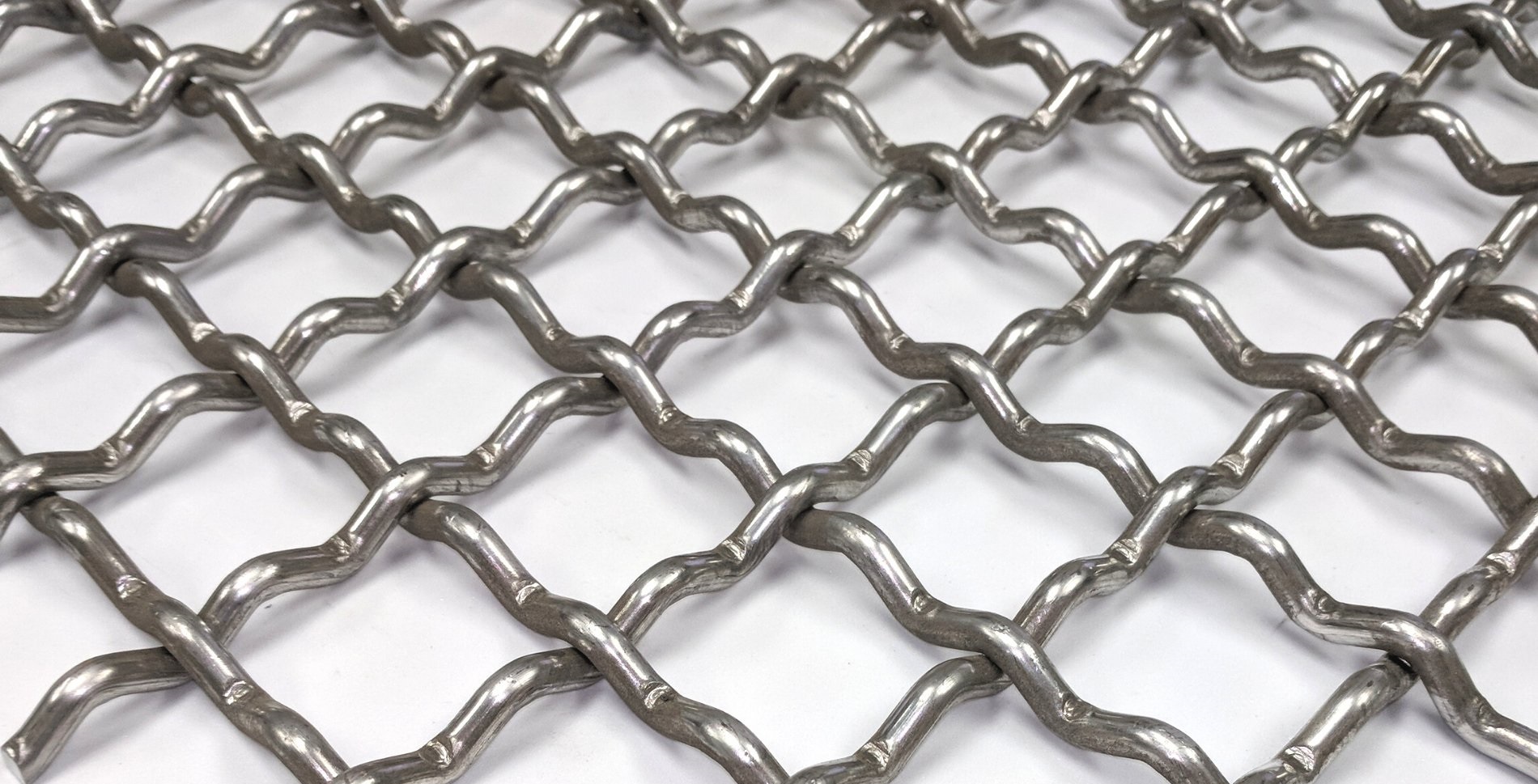

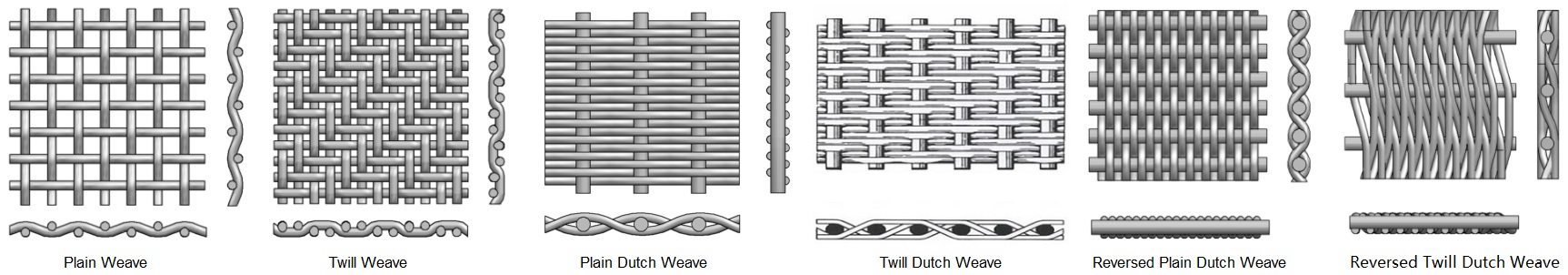

Pattern of Weave: Plain and Twill Weave, Plain & Twill Dutch Weave, Crimped.

Mesh Count: 0.5 to 325Mesh,up to 1400mesh for Dutch Weave

Wire Diameter: 3mm to 0.035mm

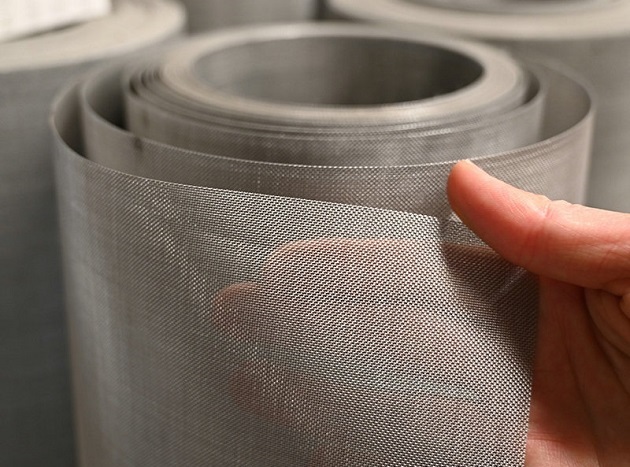

Roll Width: Customized.

Roll Length: Standard 30 meters roll or customized length.

Super Alloy 904L Wire Mesh is well-known for its UNS equivalent S08904 wire mesh and DIN number 1.4539 Mesh.

This alloy is a non-stabilized austenitic stainless steel with low carbon content. The addition of copper elements helps to develop resistance to sulphuric acid and other reducing agents in both aggressive and mild conditions.

904L alloy screen mesh products have good resistance to general corrosion and much other corrosion including pitting & crevice corrosion, intergranular corrosion, and stress corrosion cracking.

Grade 904L mesh is non-magnetic, and it has good formability, toughness, and weldability. With high amounts of expensive ingredients, such as molybdenum and nickel it performs well in warm seawater and prevents chloride attacks.

METART manufactures 904L woven wire mesh up to 200x200 for plain weave patterns, 325x325Mesh for twill weave patterns, and 250x2400Mesh for twill dutch weave.

|

EQUIVALENT STANDARDS OF ALLOY 904L WIRE MESH |

||||

|

GB-T |

UNS |

ASTM |

EURONORMS EN |

SUS |

|

015Cr21Ni26Mo5Cu2 Mesh |

N06600 Wire Mesh |

904L Wire Mesh |

1.4539 Wire Mesh X1NiCrMoCuN25-20-5 |

… |

Chemical Composition of 904L woven wire mesh

|

Ni % |

Cr % |

Mo % |

Cu % |

Fe % |

C % |

Mn % |

Si % |

P % |

S % |

|

24.0-26.0 |

19.0-21.0 |

4.0-5.0 |

1.0-2.0 |

Balance |

0.02 |

2.0 |

1.0 |

0.045 |

0.035 |

Physical Properties of 904L wire screen.

|

Physical Properties of 904l Wire Screen |

|

|

Density |

7.95 g/cm3 (0.287 lbs/in3) |

|

Melting Point |

1300–1390°C (2372–2534°F) |

|

Ultimate Tensile Strength |

490MPA (Psi-71,000) |

|

Yield Strength (0.2%Offset) |

MPa-220 Psi-31,000 |

|

Electrical Resistivity |

95.2 Microhm-cm at 20°C (33.5 Microhm-in at 68°F) |

|

Specific Heat |

450 J/kg-°K (0–100°C) 0.11 BTU/lb-°F (32–212°F) |

|

Modulus of Elasticity |

190 GPa 28.0 x 106 psi |

|

Thermal Conductivity 212°F (100°C) |

12.9 W/m-°K 6.8 BTU/Ft-hr-°F |

|

Elongation Rate |

36% |

|

Hardness |

70–90 Rockwell B |

Plain Weave and Twill Weave 904L Mesh Regular Specification Table

|

/Inch |

Wire Diameter |

Aperture |

Open Area % |

Weight (LB) /100 Square Foot |

||

|

Inch |

MM |

Inch |

MM |

|||

|

1 × 1 |

.080 |

2.03 |

.920 |

23.37 |

84.6 |

41.1 |

|

2 × 2 |

.063 |

1.60 |

.437 |

11.10 |

76.4 |

51.2 |

|

3 × 3 |

.054 |

1.37 |

.279 |

7.09 |

70.1 |

56.7 |

|

4 × 4 |

.063 |

1.60 |

.187 |

4.75 |

56.0 |

104.8 |

|

4 × 4 |

.047 |

1.19 |

.203 |

5.16 |

65.9 |

57.6 |

|

5 × 5 |

.041 |

1.04 |

.159 |

4.04 |

63.2 |

54.9 |

|

6 × 6 |

.035 |

.89 |

.132 |

3.35 |

62.7 |

48.1 |

|

8 × 8 |

.028 |

.71 |

.097 |

2.46 |

60.2 |

41.1 |

|

10 × 10 |

.025 |

.64 |

.075 |

1.91 |

56.3 |

41.2 |

|

10 × 10 |

.020 |

.51 |

.080 |

2.03 |

64.0 |

26.1 |

|

12 × 12 |

.023 |

.584 |

.060 |

1.52 |

51.8 |

42.2 |

|

12 × 12 |

.020 |

.508 |

.063 |

1.60 |

57.2 |

31.6 |

|

14 × 14 |

.023 |

.584 |

.048 |

1.22 |

45.2 |

49.8 |

|

14 × 14 |

.020 |

.508 |

.051 |

1.30 |

51.0 |

37.2 |

|

16 × 16 |

.018 |

.457 |

.0445 |

1.13 |

50.7 |

34.5 |

|

18 × 18 |

.017 |

.432 |

.0386 |

.98 |

48.3 |

34.8 |

|

20 × 20 |

.020 |

.508 |

.0300 |

.76 |

36.0 |

55.2 |

|

20 × 20 |

.016 |

.406 |

.0340 |

.86 |

46.2 |

34.4 |

|

24 × 24 |

.014 |

.356 |

.0277 |

.70 |

44.2 |

31.8 |

|

30 × 30 |

.013 |

.330 |

.0203 |

.52 |

37.1 |

34.8 |

|

30 × 30 |

.012 |

.305 |

.0213 |

.54 |

40.8 |

29.4 |

|

30 × 30 |

.009 |

.229 |

.0243 |

.62 |

53.1 |

16.1 |

|

35 × 35 |

.011 |

.279 |

.0176 |

.45 |

37.9 |

29.0 |

|

40 × 40 |

.010 |

.254 |

.0150 |

.38 |

36.0 |

27.6 |

|

50 × 50 |

.009 |

.229 |

.0110 |

.28 |

30.3 |

28.4 |

|

50 × 50 |

.008 |

.203 |

.0120 |

.31 |

36.0 |

22.1 |

|

60 × 60 |

.0075 |

.191 |

.0092 |

.23 |

30.5 |

23.7 |

|

60 × 60 |

.007 |

.178 |

.0097 |

.25 |

33.9 |

20.4 |

|

70 × 70 |

.0065 |

.165 |

.0078 |

.20 |

29.8 |

20.8 |

|

80 × 80 |

.0065 |

.165 |

.0060 |

.15 |

23.0 |

23.2 |

|

80 × 80 |

.0055 |

.140 |

.0070 |

.18 |

31.4 |

16.9 |

|

80 × 80 |

.0047 |

.119 |

.0078 |

.198 |

39 |

11.39 |

|

90 × 90 |

.005 |

.127 |

.0061 |

.16 |

30.1 |

15.8 |

|

100 × 100 |

.0045 |

.114 |

.0055 |

.14 |

30.3 |

14.2 |

|

100 × 100 |

.004 |

.102 |

.0060 |

.15 |

36.0 |

11.0 |

|

100 × 100 |

.0035 |

.089 |

.0065 |

.17 |

42.3 |

8.3 |

|

110 × 110 |

.0040 |

.1016 |

.0051 |

.1295 |

30.7 |

12.4 |

|

120 × 120 |

.0037 |

.0940 |

.0064 |

.1168 |

30.7 |

11.6 |

|

150 × 150 |

.0026 |

.0660 |

.0041 |

.1041 |

37.4 |

7.1 |

|

160 × 160 |

.0025 |

.0635 |

.0038 |

.0965 |

36.4 |

5.94 |

|

180 × 180 |

.0023 |

.0584 |

.0033 |

.0838 |

34.7 |

6.7 |

|

200 × 200 |

.0021 |

.0533 |

.0029 |

.0737 |

33.6 |

6.2 |

|

250 × 250 |

.0016 |

.0406 |

.0024 |

.0610 |

36.0 |

4.4 |

|

270 × 270 |

.0016 |

.0406 |

.0021 |

.0533 |

32.2 |

4.7 |

|

300 × 300 |

.0051 |

.0381 |

.0018 |

.0457 |

29.7 |

3.04 |

|

325 × 325 |

.0014 |

.0356 |

.0017 |

.0432 |

30.0 |

4.40 |

Plain Dutch Weave 904L Woven Wire Regular Specifications.

|

Mesh Count |

Wire Diameter. (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

8 x 85 |

.014 x .0126 |

318-340 |

250-255 |

|

12 x 64 |

.024 x .0165 |

270-285 |

200-205 |

|

14 x 88 |

.020 x .013 |

225-245 |

150-155 |

|

20 x 150 |

.0098 x .007 |

155-165 |

100-105 |

|

24 x 100 |

.015 x .010 |

115-125 |

80-85 |

|

30 x 150 |

.009 x .007 |

95-100 |

65-70 |

|

40 x 200 |

.007 x .0055 |

65-70 |

55-60 |

|

50 x 250 |

.0055 x .0045 |

55-60 |

40-45 |

Twill Dutch Weave 904L Wire Mesh Regular Specifications Table

|

Mesh Count |

Wire Diameter (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

20 x 250 |

.0098 x .0079 |

110-120 |

98-105 |

|

30 x 360 |

.0098 x .0060 |

90-100 |

80-84 |

|

40 x 560 |

.0070 x .0040 |

70-75 |

47-52 |

|

120 x 400 |

.0040 x .0025 |

50-55 |

37-43 |

|

120 x 160 |

.0040 x .0025 |

40-45 |

28-32 |

|

80 x 700 |

.0040 x .0030 |

35-40 |

24-26 |

|

200 x 600 |

.0024 x .0018 |

28-32 |

19-21 |

|

165 x 800 |

.0028 x .0020 |

24-26 |

14-16 |

|

165 x 1400 |

.0028 x .0016 |

16-18 |

9-11 |

|

200 x 1400 |

.0028 x .0016 |

12-14 |

5-6 |

|

250 x 1400 |

.0022 x .0016 |

11-12 |

3-4 |

-Petroleum Industry, including petrochemical equipment in the reactor and Oil refinery components.

-The storage and transporting industry of sulfuric acid.

-Seawater cooling equipment or devices.

-Pulp and paper processing industries.

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY