Professional Stainless Steel Wire Mesh Manufacturer and Stockist from China.

Feel free to call or email our senior sales.

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

+61 435 598 786

+86 158 0318 7372

hello@metartmesh.com

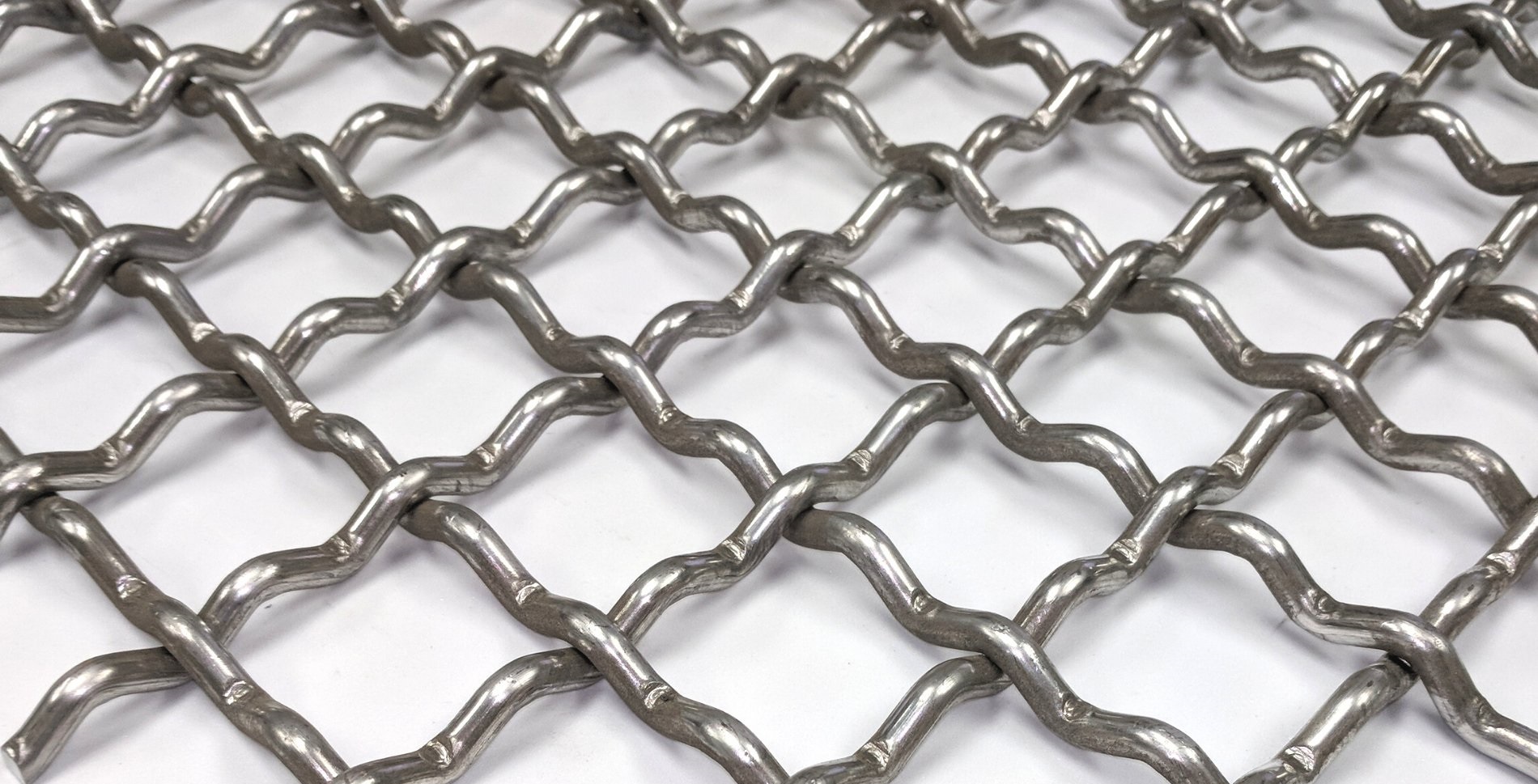

Monel 400 Wire Mesh

Material: Alloy 400 stainless steel wires

Type: Industrial Exotic Alloy Mesh

Pattern of Weave: Plain and Twill Weave, Dutch Weave, Crimped Patterns.

Mesh Count: Custom made.

Wire Diameter: Custom made.

Roll Width: Custom made

Length: 30 meters standard roll length and other customized size.

.jpg)

Nickel Alloy 400 wire mesh is also referred to as Monel 400 Wire mesh and UNS N04400 wire mesh, which is made of quality nickel-copper alloy wires that have very good resistance to seawater and steam under high temperatures. Meantime, it is also resistant to salt and caustic solutions.

Monel 400 alloy is famous for its high strength and corrosion-resistant properties. Thus, this grade of mesh is used extensively in oil refining and piping industries, due to its toughness and anti-corrosive properties.

Meantime, alloy 400 wire cloth and wire mesh are often applied in marine environments such as seawater processing screen filters.

Monel 400 has very good toughness which also makes alloy 400 wire mesh ideal for use in mining, oil & gas, cement, and nuclear power plants.

|

EQUIVALENT STANDARDS OF MONEL 400 WIRE MESH |

||||

|

NICKEL ALLOY 400 WIRE MESH |

UNS |

ASTM |

EURONORMS EN |

SUS |

| MONEL 400 WIRE MESH |

N04400 WIRE MESH |

N04400 WIRE MESH |

2.4360, 2.4361 WIRE MESH |

|

Chemical Composition of Monel® 400 wire mesh

|

C |

Mn |

S |

Si |

Ni |

Cu |

Fe |

|

.30 Max |

2.0 Max |

.024 Max |

.50 Max |

63.0 Min |

28.0-34.0 |

2.5 Max |

Physical Properties of Monel 400 Alloy Wire Screens.

|

Property |

Metric Units |

|

Melting Range |

1300-1350°C |

|

Density |

8,800 kg/m³ @ 20°C |

|

Coefficient of Thermal Expansion |

13.9 x 10 -6 / °C (20°C) |

|

Curie Temperature |

20-50°C |

|

Thermal Conductivity |

21.8 W/m. °C @ 20°C |

|

Thermal Capacity (Specific Heat) |

427 J/kg. °C @ 20°C |

|

Electrical Conductivity |

32 % IACS |

|

Electrical Resistivity |

0.547 microhm.m @ 20°C |

|

Modulus of Elasticity (tension) |

179 GPa @ 20°C |

|

Modulus of Rigidity (torsion) |

65.5 GPa @ 20°C |

|

Poisson’s Ratio |

0.32 |

Regular Specification Table for plain weave and twill weave monel 400 wire mesh

|

/Inch |

Wire Diameter |

Aperture |

Open Area % |

Weight (LB) /100 Square Foot |

||

|

Inch |

MM |

Inch |

MM |

|||

|

1 × 1 |

.080 |

2.03 |

.920 |

23.37 |

84.6 |

41.1 |

|

2 × 2 |

.063 |

1.60 |

.437 |

11.10 |

76.4 |

51.2 |

|

3 × 3 |

.054 |

1.37 |

.279 |

7.09 |

70.1 |

56.7 |

|

4 × 4 |

.063 |

1.60 |

.187 |

4.75 |

56.0 |

104.8 |

|

4 × 4 |

.047 |

1.19 |

.203 |

5.16 |

65.9 |

57.6 |

|

5 × 5 |

.041 |

1.04 |

.159 |

4.04 |

63.2 |

54.9 |

|

6 × 6 |

.035 |

.89 |

.132 |

3.35 |

62.7 |

48.1 |

|

8 × 8 |

.028 |

.71 |

.097 |

2.46 |

60.2 |

41.1 |

|

10 × 10 |

.025 |

.64 |

.075 |

1.91 |

56.3 |

41.2 |

|

10 × 10 |

.020 |

.51 |

.080 |

2.03 |

64.0 |

26.1 |

|

12 × 12 |

.023 |

.584 |

.060 |

1.52 |

51.8 |

42.2 |

|

12 × 12 |

.020 |

.508 |

.063 |

1.60 |

57.2 |

31.6 |

|

14 × 14 |

.023 |

.584 |

.048 |

1.22 |

45.2 |

49.8 |

|

14 × 14 |

.020 |

.508 |

.051 |

1.30 |

51.0 |

37.2 |

|

16 × 16 |

.018 |

.457 |

.0445 |

1.13 |

50.7 |

34.5 |

|

18 × 18 |

.017 |

.432 |

.0386 |

.98 |

48.3 |

34.8 |

|

20 × 20 |

.020 |

.508 |

.0300 |

.76 |

36.0 |

55.2 |

|

20 × 20 |

.016 |

.406 |

.0340 |

.86 |

46.2 |

34.4 |

|

24 × 24 |

.014 |

.356 |

.0277 |

.70 |

44.2 |

31.8 |

|

30 × 30 |

.013 |

.330 |

.0203 |

.52 |

37.1 |

34.8 |

|

30 × 30 |

.012 |

.305 |

.0213 |

.54 |

40.8 |

29.4 |

|

30 × 30 |

.009 |

.229 |

.0243 |

.62 |

53.1 |

16.1 |

|

35 × 35 |

.011 |

.279 |

.0176 |

.45 |

37.9 |

29.0 |

|

40 × 40 |

.010 |

.254 |

.0150 |

.38 |

36.0 |

27.6 |

|

50 × 50 |

.009 |

.229 |

.0110 |

.28 |

30.3 |

28.4 |

|

50 × 50 |

.008 |

.203 |

.0120 |

.31 |

36.0 |

22.1 |

|

60 × 60 |

.0075 |

.191 |

.0092 |

.23 |

30.5 |

23.7 |

|

60 × 60 |

.007 |

.178 |

.0097 |

.25 |

33.9 |

20.4 |

|

70 × 70 |

.0065 |

.165 |

.0078 |

.20 |

29.8 |

20.8 |

|

80 × 80 |

.0065 |

.165 |

.0060 |

.15 |

23.0 |

23.2 |

|

80 × 80 |

.0055 |

.140 |

.0070 |

.18 |

31.4 |

16.9 |

|

80 × 80 |

.0047 |

.119 |

.0078 |

.198 |

39 |

11.39 |

|

90 × 90 |

.005 |

.127 |

.0061 |

.16 |

30.1 |

15.8 |

|

100 × 100 |

.0045 |

.114 |

.0055 |

.14 |

30.3 |

14.2 |

|

100 × 100 |

.004 |

.102 |

.0060 |

.15 |

36.0 |

11.0 |

|

100 × 100 |

.0035 |

.089 |

.0065 |

.17 |

42.3 |

8.3 |

|

110 × 110 |

.0040 |

.1016 |

.0051 |

.1295 |

30.7 |

12.4 |

|

120 × 120 |

.0037 |

.0940 |

.0064 |

.1168 |

30.7 |

11.6 |

|

150 × 150 |

.0026 |

.0660 |

.0041 |

.1041 |

37.4 |

7.1 |

|

160 × 160 |

.0025 |

.0635 |

.0038 |

.0965 |

36.4 |

5.94 |

|

180 × 180 |

.0023 |

.0584 |

.0033 |

.0838 |

34.7 |

6.7 |

|

200 × 200 |

.0021 |

.0533 |

.0029 |

.0737 |

33.6 |

6.2 |

|

250 × 250 |

.0016 |

.0406 |

.0024 |

.0610 |

36.0 |

4.4 |

|

270 × 270 |

.0016 |

.0406 |

.0021 |

.0533 |

32.2 |

4.7 |

|

300 × 300 |

.0051 |

.0381 |

.0018 |

.0457 |

29.7 |

3.04 |

|

325 × 325 |

.0014 |

.0356 |

.0017 |

.0432 |

30.0 |

4.40 |

Plain Dutch Woven Monel 400 Filter Mesh Specification Table.

|

Mesh Count |

Wire Diameter. (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

8 x 85 |

.014 x .0126 |

318-340 |

250-255 |

|

12 x 64 |

.024 x .0165 |

270-285 |

200-205 |

|

14 x 88 |

.020 x .013 |

225-245 |

150-155 |

|

20 x 150 |

.0098 x .007 |

155-165 |

100-105 |

|

24 x 100 |

.015 x .010 |

115-125 |

80-85 |

|

30 x 150 |

.009 x .007 |

95-100 |

65-70 |

|

40 x 200 |

.007 x .0055 |

65-70 |

55-60 |

|

50 x 250 |

.0055 x .0045 |

55-60 |

40-45 |

Monel 400 Twill Dutch Woven Wire Mesh Specification Table.

|

Mesh Count |

Wire Diameter (In.) |

Absolute Filtration Fineness (μm) |

Nominal Filtration Fineness (μm) |

|

20 x 250 |

.0098 x .0079 |

110-120 |

98-105 |

|

30 x 360 |

.0098 x .0060 |

90-100 |

80-84 |

|

40 x 560 |

.0070 x .0040 |

70-75 |

47-52 |

|

120 x 400 |

.0040 x .0025 |

50-55 |

37-43 |

|

120 x 160 |

.0040 x .0025 |

40-45 |

28-32 |

|

80 x 700 |

.0040 x .0030 |

35-40 |

24-26 |

|

200 x 600 |

.0024 x .0018 |

28-32 |

19-21 |

|

165 x 800 |

.0028 x .0020 |

24-26 |

14-16 |

|

165 x 1400 |

.0028 x .0016 |

16-18 |

9-11 |

|

200 x 1400 |

.0028 x .0016 |

12-14 |

5-6 |

|

250 x 1400 |

.0022 x .0016 |

11-12 |

3-4 |

-Engineering in the marine environment.

-Filter screens in the chemical processing industry.

-Filter screen in crude petroleum stills

-Industrial heat exchanger components.

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY