Post time: 07 12,2022

The History and Evolution of Wire Mesh

What is Wire Mesh?

Wire mesh, also referred to as wire cloth, is a type of textile that has gained widespread popularity over the past hundreds of years, thanks to its many benefits and versatility.

Unlike traditional cotton textiles, wire mesh is generally made of metal or alloy wires that are woven together in a variety of patterns and styles, using a specialized loom.

The earliest use of wire mesh

The earliest recorded use of wire mesh can be traced back to ancient Egypt, where gold and silver were fashioned into intricate and beautiful jewelry. This technique was later adopted by the Vikings, who were known for their innovative weaving technology. The Vikings created long tubes by successively looping wire and then stretching it, a process they referred to as "Viking Knitting".

Wire Mesh Uses in Ancient Military.

With the development of ancient wire drawing technology, the use of steel wires is getting popular. And then the use of metal woven wires in military applications begin, such as body armor and protective helmets, was also well-established in ancient times.

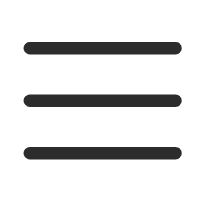

One of the most famous examples of this was chain maille armor, which consisted of small steel rings linked together in a regular pattern to form a mesh. This type of armor was used widely in Europe, Asia, and North Africa, and was referred to as a hauberk or byrnie.

This armor was made from small metal rings linked together in a mesh pattern to form a protective covering for the wearer. The use of chain mail armor dates back to ancient civilizations and has played a significant role in shaping the course of history.

This armor was made from small metal rings linked together in a mesh pattern to form a protective covering for the wearer. The use of chain mail armor dates back to ancient civilizations and has played a significant role in shaping the course of history.

The function of chain mail armor was to provide protection for the wearer against weapons such as swords, arrows, and other blunt instruments. During ancient times, warfare was a common occurrence, and soldiers needed to be protected in battle. Chain mail armor was a preferred form of armor due to its flexibility and ability to withstand blows from weapons.

Unlike other forms of armor that were heavy and stiff, chain mail armor allowed the wearer to move freely and respond quickly to threats in battle.

Chain mail armor was made from rings that were interlinked to form a mesh. The rings were made of various materials such as iron, steel, or even gold and silver. The rings were linked together in a specific pattern to create flexible and durable armor. This design provided a significant advantage over other forms of armor as it allowed the wearer to move freely without the armor restricting their movement. Additionally, the interlocking rings provided a barrier against weapons, preventing them from penetrating the armor and injuring the wearer.

Chain mail armor was also very versatile, and it could be worn over various parts of the body, such as the torso, arms, legs, and even the head. The design of chain mail armor allowed for it to be easily adapted to different forms of protection. For instance, some soldiers wore chainmail gloves to protect their hands, while others wore chainmail hoods to protect their heads. Additionally, chain mail armor could be worn as a full suit of armor, providing complete protection for the body.

Chain mail armor was also very versatile, and it could be worn over various parts of the body, such as the torso, arms, legs, and even the head. The design of chain mail armor allowed for it to be easily adapted to different forms of protection. For instance, some soldiers wore chainmail gloves to protect their hands, while others wore chainmail hoods to protect their heads. Additionally, chain mail armor could be worn as a full suit of armor, providing complete protection for the body.

One of the most significant advantages of chain mail armor was its ability to absorb energy from weapons. When a weapon struck the armor, the energy was dispersed over a large area, reducing the impact of the weapon. This meant that chain mail armor was able to provide better protection against weapons compared to other forms of armor.

One of the most significant advantages of chain mail armor was its ability to absorb energy from weapons. When a weapon struck the armor, the energy was dispersed over a large area, reducing the impact of the weapon. This meant that chain mail armor was able to provide better protection against weapons compared to other forms of armor.

Another advantage of chainmail armor was its resistance to rust. Unlike other forms of armor that were made from metal, chain mail armor was able to resist rust due to its interlocking design. This meant that chain mail armor could last for years, even in harsh conditions. This durability allowed soldiers to rely on their chainmail armor for protection in battle, providing peace of mind and confidence in their ability to defend themselves.

Despite its advantages, chain mail armor was not invincible. The armor could be penetrated by weapons such as axes, spears, and maces that were designed to break through chain mail. Additionally, chain mail armor could be damaged by weapons that had sharp edges, such as swords. To combat these limitations, soldiers would often wear additional layers of armor, such as a leather or cloth underlayer, to provide additional protection.

Despite its advantages, chain mail armor was not invincible. The armor could be penetrated by weapons such as axes, spears, and maces that were designed to break through chain mail. Additionally, chain mail armor could be damaged by weapons that had sharp edges, such as swords. To combat these limitations, soldiers would often wear additional layers of armor, such as a leather or cloth underlayer, to provide additional protection.

In conclusion, chain mail armor played a significant role in the ancient world by providing protection for soldiers in battle. Its flexibility, durability, and resistance to rust made it an excellent choice for armor. The interlocking rings of chain mail allowed for the energy of weapons to be dispersed over a large area, reducing the impact of the weapon and providing better protection. Despite its limitations, chain mail armor was a preferred form of armor for many soldiers, and its legacy continues to be remembered today.

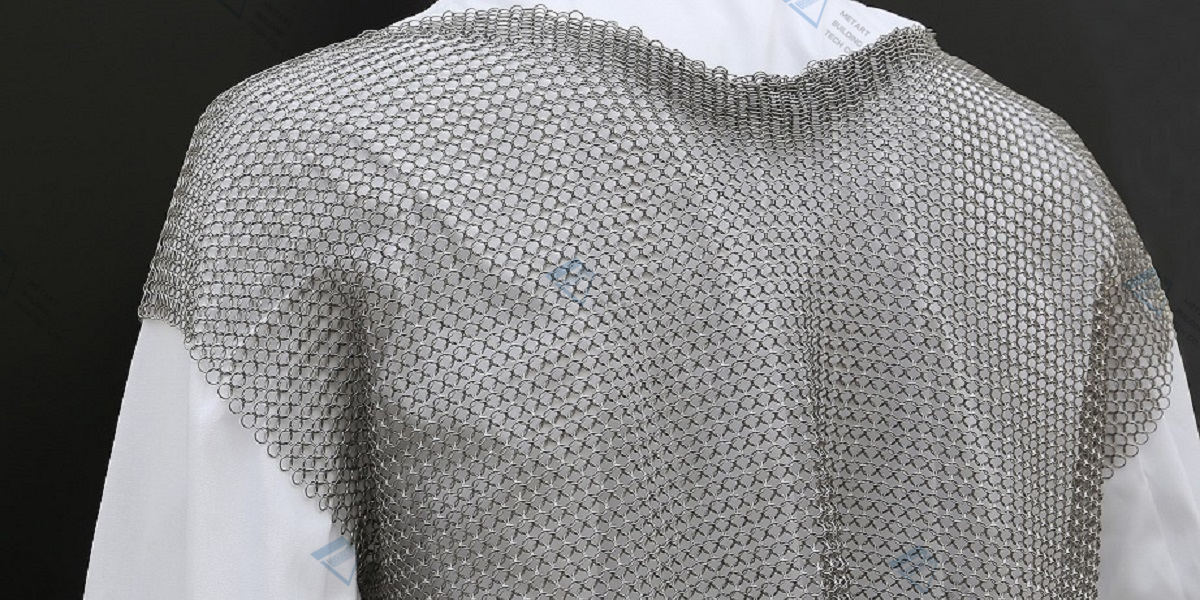

With the invention of the first power loom in 1786, wire mesh quickly gained popularity for both industrial and residential applications. The ability to mass-produce wire mesh through the use of machines revolutionized its use, and it has continued to evolve and develop over the years.

Over the next 100 years, the technology continued to evolve and improve, with the introduction of new weaving patterns, styles, and machines. In the 19th and 20th centuries, the use of wire mesh expanded into a variety of industries, including construction, agriculture, and filtration. The development of wire mesh also led to the creation of new materials, such as different grades of stainless steel and many kinds of other special super alloy corrosion-resistant metals, which further improved its functionality and durability under critical environments.

The Rise of Chinese Wire Mesh Weaving.

The history of Chinse wire mesh weaving originated in our city, Anping County, located in the northern part of China, and is widely recognized as the birthplace and now the base of wire mesh production in China. The history of wire mesh production in Anping dates back to the Ming Dynasty (1368-1644), when the first wire fabric mill was established to produce silk, cotton, and horsetail hair fabrics. This small city was strategically located near the capital of Beijing, making it an ideal place to produce wire mesh as it was well-connected to the transportation network, which facilitated the export of wire mesh to other regions.

In the early days, these wire fabrics were all produced using traditional hand-weaving techniques. The process was time-consuming and labor-intensive, and the resulting product was of lower quality and costlier compared to those produced using modern methods

In the early days, these wire fabrics were all produced using traditional hand-weaving techniques. The process was time-consuming and labor-intensive, and the resulting product was of lower quality and costlier compared to those produced using modern methods

The development of wire mesh production in Anping took a leap forward in the 20th century with the introduction of modern machinery. The first power loom for wire mesh production was introduced in Anping in the early 1920s, which greatly increased production efficiency and reduced costs. This paved the way for Anping to become a major center for wire mesh production in China and even in the world.

During the 20th century, the wire mesh industry in Anping continued to grow and evolve, with more advanced production technologies being introduced and new wire mesh products being developed. In the 1950s, stainless steel wire mesh was first produced in Anping, which further boosted the development of the wire mesh industry.

The wire mesh industry in Anping was also supported by the local government, which provided subsidies and established technical training centers to help local wire mesh manufacturers to improve their competitiveness. This led to a significant improvement in the quality of wire mesh products produced in Anping, making it a sought-after supplier of wire mesh products globally.

In conclusion, the history of wire mesh production in Anping is a testament to the town's rich industrial heritage and its significant contribution to the development of wire mesh production in China and beyond. The town's wire mesh industry has come a long way since its early days and continues to thrive, providing high-quality wire mesh products to customers around the world.

The Innovation of wire mesh

As technology advanced, so did the versatility and versatility of wire mesh. The development of computer-aided design (CAD) and computer-controlled weaving machines made it possible to create highly customized and complex woven patterns, with precise specifications and tolerances.

And the ancient armor chainmail is gradually been favored by more and more designers and architects. This ancient wire mesh finally become a popular stylish metal curtain drapery for commercial buildings, conference centers, exhibition centers, and art centers as interior decorative partitions or privacy metal curtains. Who knows one day this armor wire mesh can change from a weapon to a piece of art that would bring you peace in your mind one day. Hopefully, one day, there is no war in this world, only peace and love.

With the help of intricate tooling designs, people started to research and develop a wide range of decorative wire mesh patterns for architectural uses. And thanks to the diverse and highly developed surface treatment technology, these stylish architectural woven wire mesh can be painted, coated, or plated with different color finishes. Thus, metal wire mesh products are favored by more and more designers and architects both in interior and exterior decorations, including cabinetry door wire mesh grilles, decorative partition metal screen infills, railing system infills, architectural fencing wire mesh panels, furniture decorative woven wire screens, air vents screen panels, wall cladding decorative wire mesh, hotel decoration wire mesh, lift cabin cladding mesh, building façade architectural wire mesh, solar control wire mesh screens, screen door infill security mesh, etc.

With the help of intricate tooling designs, people started to research and develop a wide range of decorative wire mesh patterns for architectural uses. And thanks to the diverse and highly developed surface treatment technology, these stylish architectural woven wire mesh can be painted, coated, or plated with different color finishes. Thus, metal wire mesh products are favored by more and more designers and architects both in interior and exterior decorations, including cabinetry door wire mesh grilles, decorative partition metal screen infills, railing system infills, architectural fencing wire mesh panels, furniture decorative woven wire screens, air vents screen panels, wall cladding decorative wire mesh, hotel decoration wire mesh, lift cabin cladding mesh, building façade architectural wire mesh, solar control wire mesh screens, screen door infill security mesh, etc.

Today, wire mesh continues to play an important role in many industries and is used in a wide range of applications, from building enclosing, fencing, and screens to aerospace and biomedical applications. The development of wire mesh weaving technology has truly come a long way and will likely continue to evolve and improve in the future.

Today, wire mesh continues to play an important role in many industries and is used in a wide range of applications, from building enclosing, fencing, and screens to aerospace and biomedical applications. The development of wire mesh weaving technology has truly come a long way and will likely continue to evolve and improve in the future.

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY